Deciding between a pre-engineered solution and a custom build is a critical choice for any business aiming to enhance its operations. While a custom-built system might seem like the perfect tailored fit, pre-engineered solutions consistently provide a faster, more reliable, and cost-effective path to success. Making the right choice empowers your business to overcome challenges and achieve its long-term vision.

This article explores the definitive advantages of choosing a pre-engineered solution. We will break down why these proven systems outperform custom alternatives in critical areas like cost, deployment speed, reliability, and support. Understanding these benefits will equip you with the knowledge to make a confident, strategic investment in your company's future.

Pre-Engineered Systems Reduce Initial Costs

One of the most significant advantages of a pre-engineered system is its lower upfront cost. These solutions leverage standardized designs and components, which manufacturers produce in higher volumes. This economy of scale directly translates into savings for your business. In contrast, a custom build starts from scratch. It requires unique design, engineering, and fabrication processes that are inherently more expensive and time-consuming. By choosing a pre-engineered option, you avoid the high costs associated with custom development, freeing up capital for other essential business investments.

Pre-Engineered Solutions Offer Faster Deployment

Time is a resource you cannot recover. A pre-engineered solution offers a dramatically shorter timeline from purchase to operation. Since the design and engineering phases are already complete, the system can be manufactured and installed quickly. Custom builds involve a lengthy process of consultation, design, prototyping, testing, and refinement that can take months or even years. This extended timeline means a longer wait to see any return on your investment. A pre-engineered system gets you up and running faster, allowing you to boost productivity and profitability without unnecessary delays.

Proven Reliability Is a Core Benefit

With a pre-engineered solution, you invest in a system that has already been tested, refined, and proven in real-world applications. These systems have undergone rigorous quality control and have a documented track record of performance across various industries. This history of reliability provides peace of mind that is simply not available with a custom build. A new custom solution is an unknown quantity; you become the test case, which can lead to unexpected issues, downtime, and costly corrections. Choosing a proven system ensures you receive a dependable solution right from the start.

They Simplify the Integration Process

Integrating new equipment into existing workflows can be a major challenge. Pre-engineered solutions are designed with integration in mind. Manufacturers develop them to be compatible with common industry standards and equipment, making the setup process much smoother. They often come with comprehensive documentation and established integration protocols. A custom build, on the other hand, requires a unique integration strategy that can introduce unforeseen complexities and compatibility issues, disrupting your operations.

You Receive Superior Technical Support

When you invest in a pre-engineered system, you gain access to a dedicated and experienced support team. The manufacturer's technicians are experts on the solution because they have dealt with it extensively. This deep knowledge allows them to diagnose and resolve issues quickly and effectively. With a custom build, finding adequate support can be difficult. The expertise often resides with a small team or even a single engineer, making it challenging to get timely help when you need it most.

You Benefit From Predictable Performance

Predictability is essential for effective business planning. Pre-engineered solutions offer a high degree of performance certainty.

Output rates are well-documented.

Operational costs are clearly defined.

Maintenance requirements are scheduled and known.

This predictability allows you to forecast production, manage budgets, and allocate resources with confidence. Custom builds introduce significant performance uncertainty. Since the system is unproven, its actual output and operational costs may differ from initial projections, making it difficult to plan effectively.

They Ensure Future-Proof Scalability

Leading manufacturers design pre-engineered systems with scalability in mind. As your business grows, you can often add modules or upgrade components seamlessly to increase capacity. This built-in scalability provides a clear growth path and protects your initial investment. Scaling a custom build is often more complex and expensive. It may require a complete redesign or significant re-engineering, effectively forcing you to start the custom process all over again.

They Leverage Collective Industry Knowledge

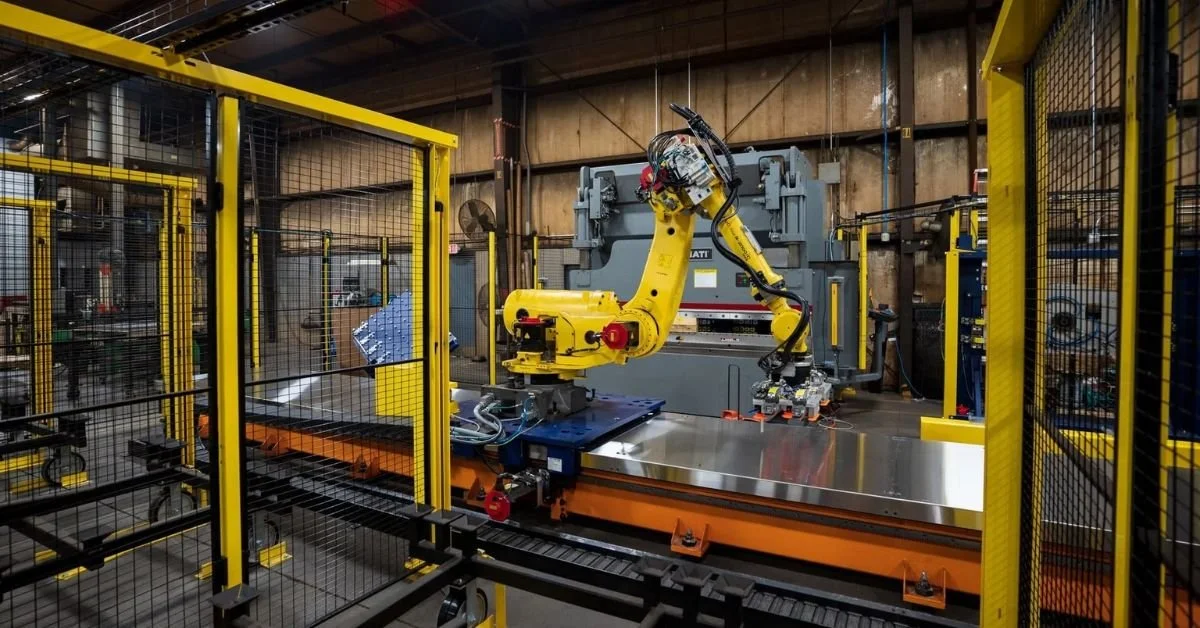

Pre-engineered solutions are the product of years of industry experience and customer feedback. Manufacturers continually refine their designs based on a wide range of applications and challenges, incorporating best practices into every unit. This collective knowledge is a powerful asset that you benefit from immediately. A custom build, by nature, is limited to the experience and vision of a single design team, potentially missing out on broader industry insights that enhance performance and reliability in manufacturing automation.

Higher Resale Value Protects Your Investment

Market demand for standardized, proven equipment is consistently higher than for unique, custom-built machines. A pre-engineered solution from a reputable manufacturer retains more of its value over time. If your business needs change and you decide to sell the equipment, you are more likely to achieve a favorable return. A custom build is tailored to a specific, narrow application, which severely limits its appeal to other buyers and reduces its potential resale value.

They Are Designed With Safety and Compliance in Mind

Safety is non-negotiable. Pre-engineered solutions are developed to meet or exceed established industry safety standards and regulatory requirements. This focus on compliance minimizes risk and helps ensure a safe working environment for your team. Developing a custom solution places the burden of ensuring compliance squarely on your shoulders. This process can be complex and time-consuming, and any oversight can lead to safety hazards and potential legal liabilities.

Make the Confident Choice

Choosing a pre-engineered solution is a strategic decision that delivers immediate and long-term benefits. These systems provide a clear advantage through reduced costs, faster implementation, and proven reliability. By opting for a solution that is already tested, supported, and optimized, you empower your business to operate more efficiently and compete more effectively. Take the next step toward enhancing your productivity and securing your company's future by choosing the proven path to success.