Manufacturing facilities across America face mounting pressure to increase productivity while maintaining precision and reducing costs. CNC machine retrofitting for automation offers a powerful solution that transforms existing equipment into highly efficient, autonomous production systems. This approach delivers immediate benefits without the massive capital investment required for complete equipment replacement.

Retrofitting your CNC machines unlocks substantial productivity gains, reduces labor costs, and positions your operation for long-term competitiveness. Smart manufacturers recognize that automation retrofits provide the fastest path to operational excellence while maximizing return on existing investments.

What Does CNC Machine Retrofitting for Automation Involve?

CNC retrofitting involves integrating automated systems with existing machining equipment to create seamless, autonomous operations. This process transforms manual or semi-manual machines into fully automated production cells that operate with minimal human intervention.

The retrofit process typically includes upgrading control systems, adding robotic components, implementing safety systems, and integrating monitoring technology. These modifications enable machines to run continuously, handle part loading and unloading automatically, and maintain consistent quality standards throughout production cycles.

Why Choose Retrofitting Over Buying New Equipment?

Retrofitting delivers exceptional value by leveraging your existing equipment investments while adding cutting-edge automation capabilities. New CNC machines can cost hundreds of thousands of dollars, while retrofitting typically requires 30–50 percent less capital investment versus buying new machines with automation.

Your current machines already occupy optimized floor space and integrate with existing workflows. Retrofitting preserves these advantages while dramatically improving performance, making it the most cost-effective path to automation for most facilities.

What Are the Key Benefits of CNC Automation Retrofits?

Automated CNC systems deliver measurable improvements across multiple performance metrics:

Productivity increases through continuous operation and faster cycle times

Labor cost reduction by eliminating manual part handling and machine tending

Quality improvements through consistent, repeatable processes

Reduced scrap rates from automated quality control and monitoring

Enhanced worker safety by removing operators from hazardous environments

24/7 production capability that maximizes equipment utilization

Which CNC Machines Work Best for Automation Retrofits?

Most CNC machines manufactured within the last 15–20 years offer excellent retrofit potential. Machines with modern control systems, adequate structural integrity, and accessible work envelopes typically adapt well to automation upgrades. However, even older equipment with outdated control systems and limited work envelopes can still see improvements in productivity and efficiency through retrofits.

5-Axis CNCs, vertical machining centers, horizontal mills, and turning centers represent the most common and successful retrofit applications. These machines benefit significantly from automated part handling, tool changing, and quality inspection systems.

New developments in automation technology make it easier than ever to integrate automated systems into existing CNC machines. Advanced software and sensor technologies provide flexibility and accuracy in part handling, tool changing, and quality inspection. This allows for quick and seamless integration with existing control systems, minimizing disruption to production processes.

How Do You Assess Your Current Equipment for Retrofit Potential?

Start by evaluating your machines' mechanical condition, control system capabilities, and structural integrity. Machines requiring frequent repairs or showing significant wear may not justify retrofit investments.

Examine work envelope accessibility, electrical system capacity, and available floor space around each machine. Document current cycle times, setup procedures, and operator requirements to establish baseline performance metrics for comparison.

What Automation Components Should You Consider?

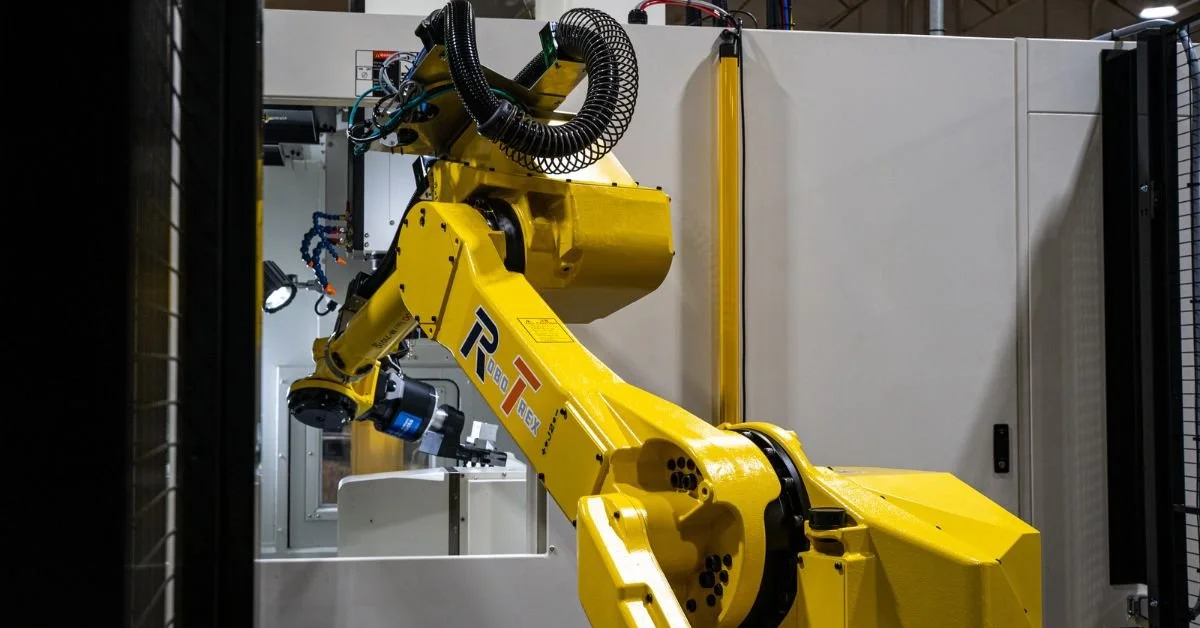

Successful CNC retrofits typically incorporate several key automation technologies. Robotic part handling systems eliminate manual loading and unloading while maintaining precise positioning and consistent cycle times. The Robotrex CNC machine tending robot exemplifies advanced automation technology designed specifically for manufacturing environments.

Automated tool changing systems are essential when considering lights-out operation. Additional key machining accessories include tool breakage detection probes and tool wear monitoring systems that help with overall quality control and ensure consistent part manufacturing without manual intervention.

How Do You Plan the Retrofit Implementation Process?

Effective retrofit planning begins with detailed production analysis and clear objective setting. Identify specific bottlenecks, labor requirements, and quality challenges that automation will address.

Develop implementation timelines that minimize production disruption. Consider phased installations that allow continued operation during upgrades. Coordinate with equipment suppliers, automation specialists, and facility personnel to ensure smooth execution.

What Safety Considerations Apply to Automated CNC Systems?

Automated systems require comprehensive safety protocols that protect both equipment and personnel. Install proper machine guarding, emergency stop systems, and light curtains around automated work cells.

Implement lockout/tagout procedures specifically designed for automated equipment. Train operators on new safety protocols and emergency response procedures. Regular safety audits ensure continued compliance with OSHA requirements and industry best practices.

How Do You Train Operators for Automated Systems?

Operator training focuses on system monitoring, troubleshooting, and maintenance rather than manual machine operation. Develop comprehensive training programs covering automation software, robotic programming basics, and quality control procedures.

Emphasize preventive maintenance responsibilities and system optimization techniques. Crosstrain multiple operators to ensure continuous coverage and reduce dependency on individual personnel. Regular refresher training keeps skills current as systems evolve.

What Programming Changes Support Automated Operation?

CNC programs require modifications to optimize automated operation and integrate with robotic systems. Standardize tool paths, cutting parameters, and cycle sequences to ensure predictable timing and performance.

Implement automated quality checks within machining programs. Add communication protocols that coordinate CNC operations with robotic systems. Be sure to develop program templates that streamline setup for new parts and reduce programming time.

How Do You Maintain Automated CNC Systems?

Preventive maintenance becomes even more critical with automated systems due to increased utilization and complexity. Develop detailed maintenance schedules covering mechanical, electrical, and software components.

Monitor system performance continuously using built-in diagnostics and data collection capabilities. Schedule regular inspections of robotic components, sensors, and safety systems. Maintain spare parts inventory specifically for automation components to minimize downtime.

What Return on Investment Can You Expect?

Most CNC automation retrofits deliver positive ROI within 12–18 months through reduced labor costs and increased production capacity. Facilities typically see payback periods of 6–24 months, depending on application complexity and production volumes.

You can calculate ROI based on labor savings, productivity improvements, quality enhancements, and reduced scrap rates. Include long-term benefits such as enhanced competitiveness, improved customer satisfaction, and increased market opportunities in your analysis.

Transform Your Manufacturing Operation Today

CNC machine retrofitting for automation represents the most practical path to manufacturing excellence for facilities ready to embrace advanced technology. This proven approach delivers immediate productivity gains while building the foundation for future growth and competitiveness.

Take decisive action to evaluate your retrofit opportunities and develop implementation plans. Partner with experienced automation specialists who understand your industry requirements and can deliver reliable, effective solutions. Your investment in CNC automation retrofitting will pay dividends for years to come through improved efficiency, quality, and profitability.