Automation represents a massive leap forward for industrial operations. It empowers businesses to scale production, improve consistency, and protect their workforce from dangerous or repetitive tasks. When you decide to automate, you face a critical choice: should you build a custom robotic cell from scratch, or should you invest in a pre-engineered robotic system? This decision significantly impacts your budget, timeline, and long-term productivity.

Pre-engineered systems, often called "off-the-shelf" solutions, have gained immense popularity. Manufacturers design these systems to handle common industrial tasks like welding, palletizing, or machine tending right out of the box. They arrive as complete packages, often including the robot, safety fencing, end-effectors, and software.

However, no single solution fits every factory floor perfectly. While these systems offer speed and simplicity, they also come with limitations that might not align with unique production needs. Understanding the specific advantages and disadvantages of pre-engineered robotic systems helps you make the best choice for your facility. Let's break down exactly what you need to know before you sign that purchase order.

What is a Pre-Engineered Robotic System?

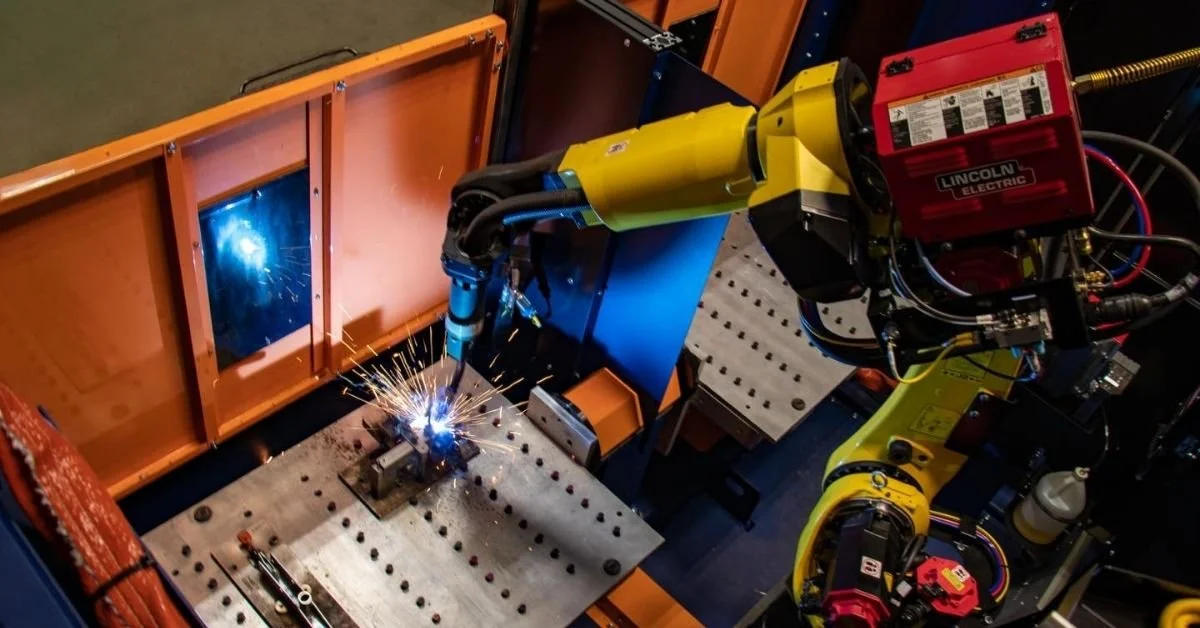

A pre-engineered robotic system functions as a standardized automation unit designed for a specific task. Unlike custom systems, which engineers design from the ground up for a unique facility, pre-engineered models follow a set template. Manufacturers build these units repeatedly, refining the design with each iteration to ensure maximum reliability and performance.

You typically buy these as a bundle. The package includes the robot arm, the controller, the necessary safety equipment, and the application-specific tooling. Because the provider has already done the heavy lifting regarding design and engineering, these systems drop into your workflow with minimal friction.

IMAGE A

Faster Deployment Speeds Up Production

Time is money in manufacturing automation. One of the most significant advantages of a pre-engineered system is the speed of deployment. Since the engineering work is already complete, lead times shrink drastically compared to custom builds. You avoid the lengthy phases of concept design, prototyping, and testing that custom projects require.

Once the system arrives at your facility, installation proceeds quickly. The components are pre-configured to work together. This means your team spends less time troubleshooting integration issues and more time producing parts. If you need to ramp up production capacity immediately, pre-engineered units offer the fastest path to ROI.

Lower Upfront Costs Protect Your Budget

Custom engineering costs add up fast. When you commission a bespoke robotic cell, you pay for every hour an engineer spends designing electrical schematics, calculating safety distances, and programming logic. Pre-engineered systems spread these non-recurring engineering costs across hundreds of units.

This shared cost structure allows manufacturers to offer pre-engineered systems at a much more attractive price point. You get a high-quality, industrial-grade solution without the premium price tag attached to one-off custom projects. For small to medium-sized businesses, this lower barrier to entry makes automation accessible where it might otherwise be cost-prohibitive.

Proven Reliability Reduces Technical Risk

Every custom machine is a prototype. No matter how skilled the engineering team is, a first-of-its-kind system will likely encounter bugs and unforeseen issues during startup. Pre-engineered systems, by contrast, have a track record. Manufacturers have likely deployed dozens or hundreds of identical units in the field.

This history means the manufacturer has already identified and fixed common failure points. The software is stable, the mechanical integration is sound, and the safety systems are verified. You invest in a mature product rather than an experiment. This reliability ensures that your production line stays running with fewer unexpected interruptions.

Simplified Support and Maintenance

Maintenance teams love standardization. When you install a custom machine, troubleshooting often requires contacting the specific engineer who designed it. If that person is unavailable, downtime stretches on. Pre-engineered systems come with standard documentation, spare parts lists, and support protocols.

Because the system is standard, parts are usually easier to source. The manufacturer likely keeps critical components in stock, rather than needing to fabricate them to order. Additionally, technical support staff can diagnose issues faster because they are familiar with the standardized configuration. This support infrastructure keeps your machines running and your maintenance headaches low.

Limited Customization Restricts Flexibility

The biggest trade-off for speed and cost is flexibility. Pre-engineered systems essentially function as "what you see is what you get." They perform specific tasks within defined parameters. If your parts are too large, too heavy, or require a complex path that falls outside the standard cell's capabilities, you might hit a wall.

Modifying a pre-engineered cell to fit a unique requirement often voids the warranty or creates new integration challenges. If your production process requires high variability or highly specialized operations, a standard "off-the-shelf" unit might not offer the adaptability you need. You must verify that your parts fit the system's specifications exactly before committing.

IMAGE B

Integration Challenges with Legacy Equipment

While the robotic cell itself is plug-and-play, integrating it with your existing factory floor might not be. Older CNC machines, conveyors, or ERP systems may not communicate easily with modern robotic controllers. A custom integrator would typically build bridges for these specific gaps during the design phase.

With a pre-engineered system, the burden of connecting it to your legacy equipment often falls on your internal team or a third-party contractor. You must make sure that your current infrastructure can support the new technology. If your facility relies on outdated communication protocols, you might face additional costs to bring everything up to speed.

Physical Footprint Constraints

Custom systems utilize every inch of available floor space efficiently. Engineers can design a custom cell to wrap around a pillar, fit into a tight corner, or hang from a gantry. Pre-engineered systems come with a fixed footprint. They are square or rectangular boxes that require a specific amount of floor space.

If your facility is crowded, finding room for a standard cell can be difficult. You cannot simply shave six inches off the safety fencing to make it fit. You must accommodate the system's dimensions, which might require rearranging other equipment or workflow paths. This rigidity forces you to adapt your facility to the robot, rather than adapting the robot to your facility.

Determining the Right Path for Your Facility

The choice between pre-engineered and custom automation ultimately depends on your specific application. If you have a standard process—like welding common brackets or palletizing standard boxes—a pre-engineered system offers unbeatable value, speed, and reliability. It allows you to automate quickly and start seeing returns immediately.

However, if your process involves unique geometries, extreme precision, or complex assembly tasks, a custom solution might be the only way to achieve your goals. Evaluate your needs carefully. Look at your part mix, your floor space, and your budget. By weighing these pros and cons, you position your business to harness the full power of automation effectively.

Transform Your Operations Today

Don't let analysis paralysis stall your progress. Automation is the key to unlocking higher throughput and better quality. Whether you choose a pre-engineered robotic solution or a custom-built marvel, the most important step is moving forward. Assess your needs, consult with experts, and take action to secure your competitive advantage.