You strive for efficiency. You demand precision. You know that to stay ahead in a competitive manufacturing landscape, you must evolve. The days of relying solely on manual labor for repetitive tasks are fading. Automation is not just a luxury anymore; it is the engine that drives modern manufacturing success.

However, deciding to automate is only the first step. The partner you choose to implement that technology matters just as much as the hardware itself. A robot arm is merely a tool, but the integration, support, and strategy behind that tool determine your return on investment. You need a provider that aligns with your vision for growth and possesses the technical expertise to execute it flawlessly.

Selecting the right partner requires a rigorous vetting process. You are not just buying a machine; you are entering a relationship that will define your production capabilities for years to come. Make the right choice, and you will unlock unprecedented productivity. Make the wrong one, and you risk costly downtime and frustration. Here is how you identify the automation partner who will help you win.

Assess Your Current Production Needs

Before you contact a single vendor, you must understand your own shop floor intimately. You cannot find a solution if you have not clearly defined the problem. Look at your current workflow with a critical eye. Identify exactly where your bottlenecks exist.

Determine if you need a system for high-volume, low-mix production or if your shop thrives on high-mix, low-volume job shop work. These two scenarios require vastly different approaches. A provider specializing in mass production transfer lines may fail to deliver the flexibility a job shop requires. You must articulate your goals clearly. Do you want to run lights-out shifts? Do you aim to relieve operators from heavy lifting? Define your objectives now so you can demand the right answers later.

Verify Their Specific Industry Experience

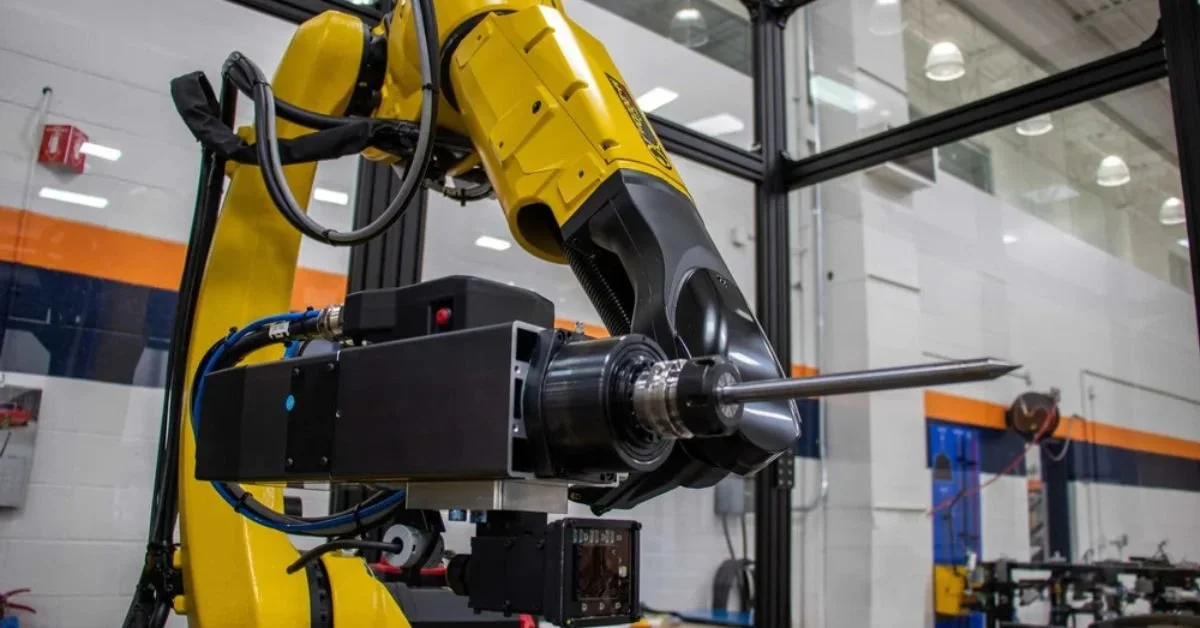

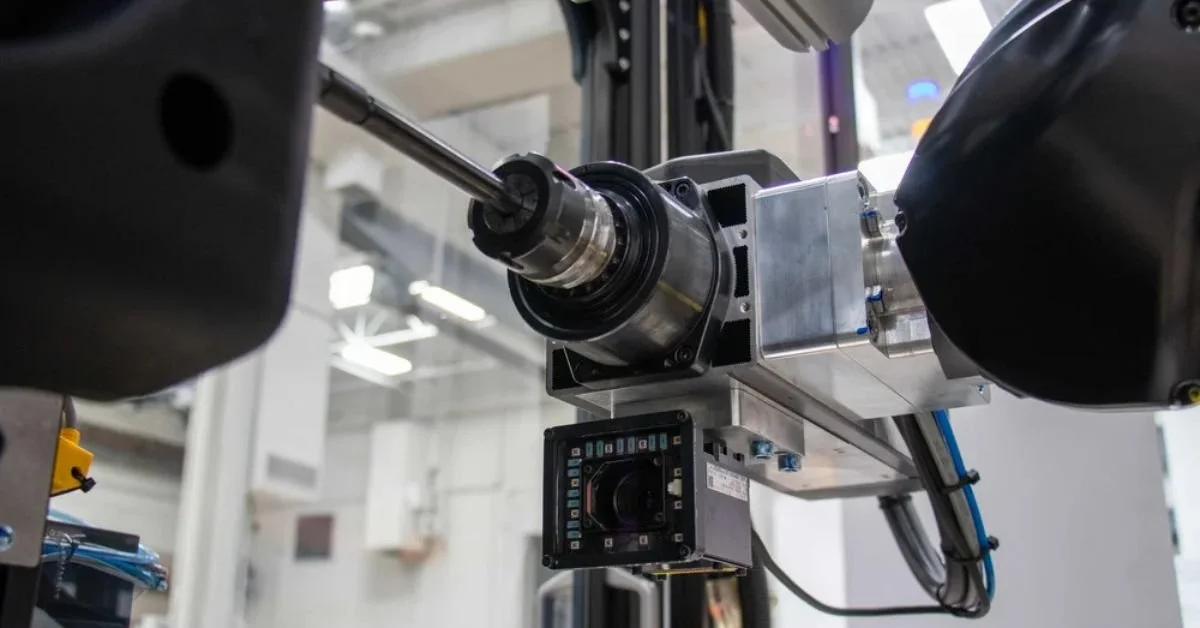

General automation experience does not always translate to CNC machine tending. You need a partner who speaks the language of machining. They must understand chip management, coolant flow, door interlocks, and workholding.

Scrutinize their track record. Ask to see examples of installations similar to what you envision. A provider who has successfully automated a lathe for a medical device manufacturer possesses different insights than one who automates palletizing for a food packaging plant. You want a team that has faced the specific challenges of your sector and overcame them. Their past success serves as the best predictor of your future results. Demand proof of their competence in your specific field.

Evaluate Their Technical Support Capabilities

Even the most robust systems require maintenance. When a machine stops, you lose money every minute it sits idle. You need a provider that guarantees rapid, effective support. Do not settle for a vendor that views the sale as the end of the relationship.

Ask pointed questions about their service infrastructure. Do they have a dedicated support line? Do they offer remote diagnostics to solve simple software issues without a site visit? You need assurance that when challenges arise, a team of experts stands ready to get you back up and running immediately. Reliability is the cornerstone of automation. Your partner must demonstrate a commitment to keeping your spindles turning.

Analyze Their Software Compatibility

Hardware attracts the eye, but software drives the results. The interface between your CNC machine and the automation system must be seamless. Clunky, unintuitive software will frustrate your operators and kill efficiency.

You need a user-friendly platform that allows for quick changeovers. If it takes a programmer four hours to set up a new part, you lose the agility that modern manufacturing demands. Look for intuitive controls that your existing workforce can master quickly. The best providers invest heavily in software that bridges the gap between complex robotics and the machinist. Ensure their system integrates flawlessly with your specific machine controls.

Review Their Safety Protocols

Safety allows for no compromise. Bringing robotic systems into a shop floor introduces new dynamic hazards. Your provider must prioritize the well-being of your workforce above all else. A safe shop is a productive shop.

Examine how they approach risk assessment. Do they adhere to the latest ISO safety standards? Do they utilize area scanners, light curtains, or force-limiting collaborative technology? You must feel confident that the system protects your employees while maintaining high throughput. A provider that cuts corners on safety puts your entire business at risk. Demand a solution that integrates safety deeply into the design, not one that treats it as an afterthought.

Examine Their Training Programs

The most advanced automation cell becomes a paperweight if your team cannot operate it. Knowledge transfer is critical to your long-term success. You need a provider that empowers your staff to take ownership of the technology.

Investigate their training curriculum. Do they offer hands-on training at your facility? Do they provide online resources for refresher courses? Your operators need to feel confident in setting up jobs, troubleshooting minor errors, and optimizing paths. Effective training bridges the skills gap and turns your machinists into automation specialists. Choose a partner that invests in your team’s growth and competence.

Check For Scalability Options

Your business will grow. Your automation partner must be ready to grow with you. Investing in a system that hits a dead end in two years wastes capital. You need industrial automation solutions that adapt to changing market demands and expanding production lines.

Can you easily add more drawers, pallets, or conveyors later? Can the robot move to a different machine if your workflow changes? A forward-thinking provider designs systems with the future in mind. They help you build a foundation for growth, ensuring that your investment today continues to pay dividends as your company scales.

Investigate Their ROI Methodology

A trustworthy partner speaks the language of profitability. They should help you build a business case that justifies the investment. Beware of providers who give vague promises of "better efficiency" without backing it up with data.

You need a clear picture of when you will see a return. A solid ROI calculation involves several key factors:

Machine uptime increases.

Labor reallocation savings.

Scrap rate reduction.

Quality consistency improvements.

Extended lights-out operating hours.

Make them walk you through the numbers. They should demonstrate exactly how their system lowers your cost per part.

Look For A Long-Term Partnership Mindset

Finally, look at the culture of the provider. You want a partner, not just a vendor. A partner celebrates your wins and works through your challenges. They care about your success because it reflects on their reputation.

Assess their communication style during the sales process. Do they listen more than they talk? Do they challenge your assumptions to find a better solution, or do they simply say "yes" to everything to get the order? You need a team that operates with integrity and transparency. Choose the company that shows a genuine interest in helping you transform your business.

Ignite Your Transformation Today

The path to automation creates the future of your manufacturing business. By rigorously evaluating potential partners against these criteria, you eliminate guesswork. You gain the confidence to move forward, knowing you have selected a team that aligns with your goals.

Do not let indecision hold you back. The technology exists to revolutionize your throughput, quality, and profitability. Take charge of your production environment. Demand excellence from your automation provider. When you choose the right partner, you do not just install a robot; you unlock a new era of growth and dominance in your industry.