The manufacturing industry rewards those who innovate. You watch competitors slash lead times and increase margins, and you know the secret lies in automation. But hesitation often stems from the unknown. You need clarity before you commit capital to new technology. You need to know if a specific system aligns with your production goals and will maximize your return on investment (ROI).

Analyzing the RoboTrex automation system requires a hard look at the facts. This system promises to revolutionize how job shops handle high-mix, low-volume production, but every business decision carries weight. Understanding the strengths and the challenges ensures you make an informed, confident choice for your company’s future. We break down the advantages and considerations of this technology, stripping away the noise so you can focus on what matters: growing your business.

Maximize Spindle Uptime To Unprecedented Levels

The primary reason you investigate automation is to keep your machines running. A standard CNC machine often sits idle while operators load parts, check measurements, or take breaks. Not to mention trying to staff second shift, third shift and weekends. RoboTrex gives you the ability to utilize this downtime and create huge gains in profitability. By utilizing pre-staged automation carts, the robot consistently feeds the machine without pauses in available production time. Your spindle utilization jumps from the industry average of 30-40% to upwards of 90%. Plus, added shifts has been proven to create 600% more productivity for shops that were working only one shift.

This massive increase in uptime transforms your P&L statement. You produce more parts in the same amount of time without buying more CNC machines or hiring more operators. You unlock the true potential of the capital equipment you already own.

Solve The Skilled Labor Shortage Crisis

Finding experienced machinists presents the single biggest challenge for modern machine shops. You post job openings, but the applications remain scarce. The "Silver Tsunami" of retiring baby boomers leaves a skills gap that the younger workforce has yet to fill. Automation provides the only viable bridge across this gap.

RoboTrex takes over the mundane, repetitive task of loading and unloading parts. This allows you to utilize your existing talent for higher-level tasks like programming, quality control, and process optimization. You stop paying skilled humans to act like robots and start empowering them to solve complex problems. This retention strategy keeps your team engaged while ensuring production never stalls due to a lack of available hands.

Unlock Lights-Out Manufacturing Potential

Imagine walking into your shop on Monday morning to find a weekend’s worth of production finished and ready for shipping. This reality defines lights-out manufacturing. The RoboTrex system allows you to run a second or third shift without adding a single employee to the payroll. You load the automation carts before the day shift leaves, press start, and let the system generate revenue while you enjoy more time with your family and even while you sleep.

This capability changes your competitive stance. You can quote tighter deadlines and lower prices because your overhead for those off-hours remains near zero. The system utilizes the automation carts to store enough raw material for extended unsupervised runs. You effectively multiply your available production hours without multiplying your labor costs.

Adapt To High-Mix Low-Volume Production

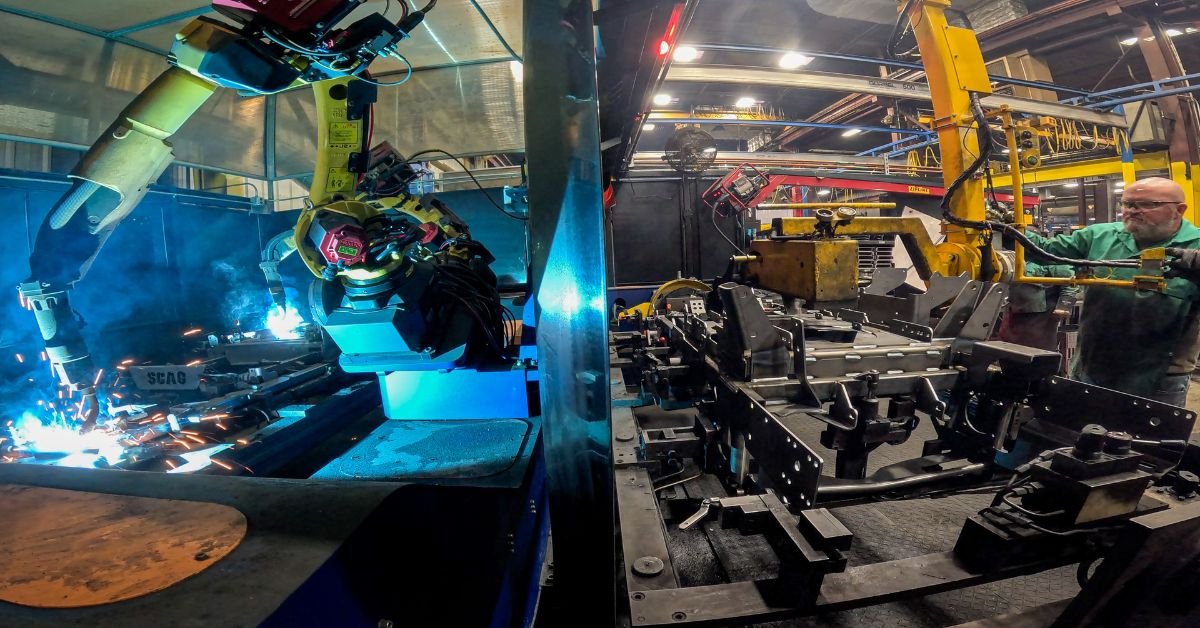

Traditional automation scares job shops because it often requires massive setup times. Old-school robotics worked best for making a million of the same part. RoboTrex flips this narrative. It specifically targets high-mix, low-volume workflows. The system uses a zero-point clamping system that allows for rapid changeovers.

You can switch from one job to the next in seconds, not hours. The automation trolleys allow you to stage different jobs on the same cart. Operators designate different programs based on the cart, or by row per cart so the robot program can tell the CNC which program to run based on the parts position. This flexibility means you can automate job lots as small as five or ten parts and still see a massive return on investment.

Ensure Consistent Part Quality Every Time

Human operators introduce variables. Fatigue, distraction, and simple errors lead to lost time sue to scrapped parts and rework. A robot performs the exact same motion with the exact same pressure at the exact same speed, every single time. This consistency guarantees that the millionth part loads look exactly like the first.

RoboTrex maintains a repeatable process that stabilizes your quality control. You reduce the variables in your manufacturing equation. When you eliminate handling errors, you increase your yield rate. Customers trust shops that deliver more parts on time. Reliability builds your reputation, and automation acts as the foundation of that reliability.

Streamline Shop Floor Space Utilization

Factory floor space costs money. You cannot afford to fill your shop with massive cages and sprawling conveyor belts. The RoboTrex CNC machine tending robot distinguishes itself with a unique storage design. By loading the system carts with rows of vises that stand on end, RoboTrex maximizes the number of parts in queue within a small footprint compared to pallet systems and other traditional automation systems.

This compact footprint often allows you to integrate the system directly next to your existing CNC machines without rearranging your entire facility. You maintain clear aisles and maximize the revenue generated per square foot of your shop. This large capacity system fits where others fail, proving that powerful automation does not require a massive expansion of your real estate.

Calculate The Return On Initial Investment

Any automation is a financial commitment. Purchasing the right robotic system can maximize your capital expenditure. You must not view RoboTrex as an expense, but as an investment engine with an incredibly short payback period and a massive ROI. The upfront cost is easily justifiable when you calculate the additional billable hours generated by lights-out running and increased spindle uptime.

Dedicate Time For Team Training

Introducing new technology requires a learning curve. Your team knows how to machine, but they may not know how to manage a robot. You must commit time and resources to training your staff. Fortunately, modern systems prioritize user experience.

No robotics expertise needed: You do not need a PhD in robotics to operate this automation.

Intuitive control: The interface uses simple logic that machinists understand.

Fast setup: Zero mechanical change-over and zero programming changes are needed from one part to the next.

With a system that is simple to operate your employees will easily embrace this new advancement as a positive change that makes their lives better.

Evaluate Part Size And Weight Limitations

No single automation solution solves every manufacturing problem. The RoboTrex system excels at handling parts that fit within its specific weight and size envelope. While it easily handles a vast range of components it has physical limits of what can fit within the vises. If your shop exclusively manufactures massive engine blocks or tiny micro-parts that require microscopic precision handling, you must verify compatibility.

You need to analyze your part mix. Identify the 80% of your work that fits the robot's capabilities and automate that. Do not reject the system because it cannot handle the 20% of outliers. Focus on the core of your business where the volume and variety align with the robot’s strengths. If your parts fit within the system’s capabilities, then you will not find a better system on the market!

Take Action To Secure Your Future

The pros heavily outweigh the cons for job shops looking to survive and thrive using Robotrex automation. The challenges of investment and training are temporary hurdles, while the benefits of productivity, consistency, and profitability last forever. You have the facts. You understand the risks and the massive rewards. The market will not wait for you to catch up.