Manufacturing evolves rapidly. To stay ahead, you must embrace change and refuse to settle for the status quo. Automation separates the leaders from the followers in today’s industrial landscape. It offers the only viable path to increasing throughput, enhancing safety, and guaranteeing consistent quality. However, buying a robot is the easy part. The true challenge lies in selecting a partner who will stand beside you from the initial design concept through final implementation and beyond.

Your choice of a robotics integrator determines the success or failure of your automation journey. The right partner empowers your business to reach new heights of productivity. The wrong one drains your budget and leaves you with expensive hardware that gathers dust. You need a collaborator who understands your vision and possesses the technical expertise to execute it flawlessly. You need a team that commits to your long-term growth.

Use these steps to evaluate potential robotics integrators. Take control of your future and make sure your investment delivers the transformative results you demand.

1. Define Your Specific Operational Goals

Before you contact a single vendor, you must clarify exactly what you want to achieve. Vague goals lead to vague solutions. Analyze your current production line with a critical eye. Identify the bottlenecks that throttle your output. Pinpoint the tasks that cause the most injuries or quality control issues.

Do you need to increase cycle speeds by 20%? Do you aim to remove operators from hazardous welding environments? Perhaps you want to run lights-out shifts to maximize revenue. When you articulate concrete objectives, you force potential partners to provide concrete answers. You drive the conversation. This clarity helps the integrator propose a solution tailored to your actual business needs rather than selling you a pre-packaged system that misses the mark.

2. Verify Their Industry-Specific Experience

Robotics is not a one-size-fits-all industry. A partner who excels in automotive assembly might fail miserably in food and beverage packaging. You require an expert who understands the unique nuances, regulations, and challenges of your specific sector.

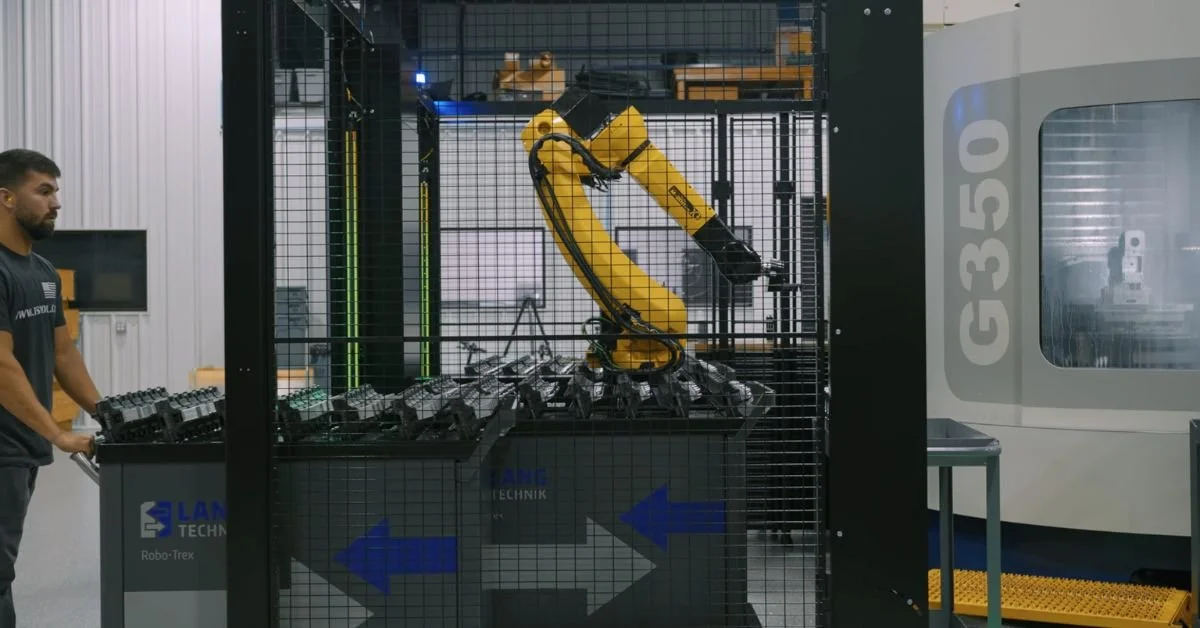

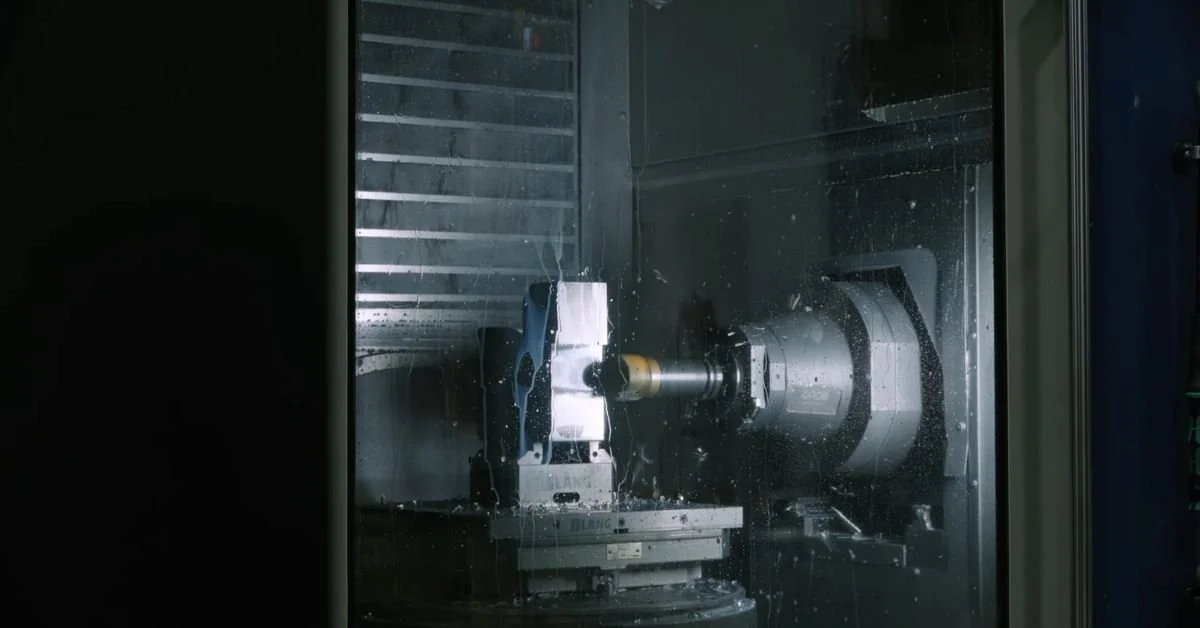

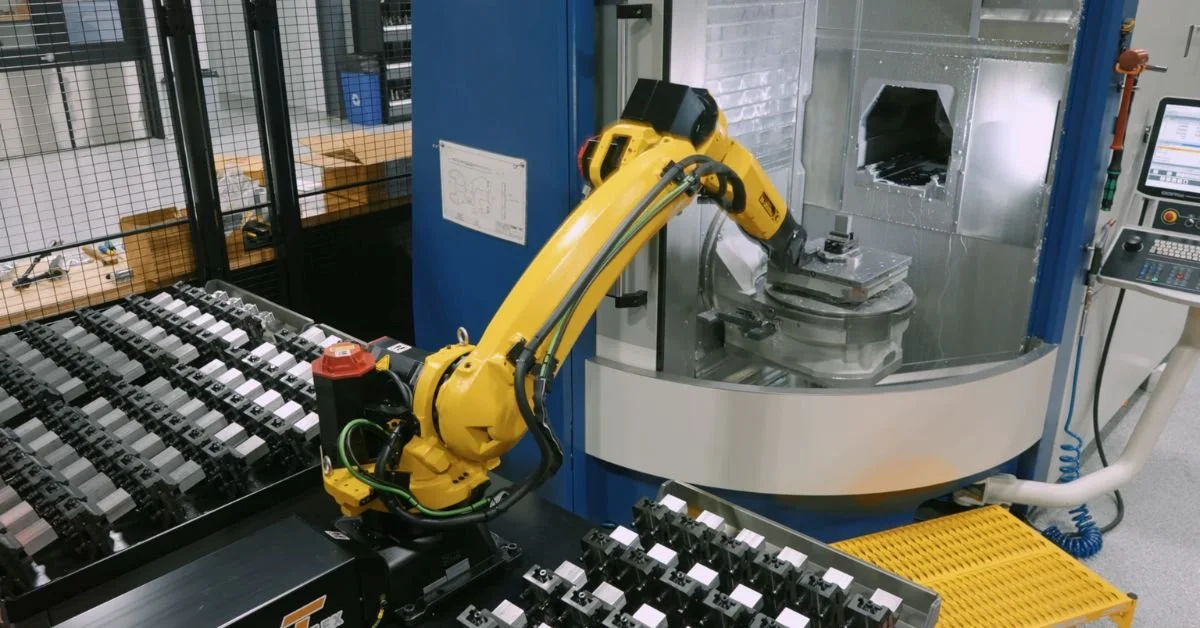

Ask for proof. Demand to see examples of previous projects that mirror your own operations. If you run a machine shop, you need a partner who understands chip management, coolant exposure, and the precise tolerances required for effective CNC automation integration. Their past success serves as the best predictor of your future results. Do not serve as their testing ground. Work with professionals who have already solved the problems you currently face.

3. Assess Their Technical Versatility

Technology moves fast. You need a partner who stays on the cutting edge. Avoid integrators tied exclusively to a single brand of robot or software unless that specific brand perfectly aligns with your needs. A vendor-agnostic partner acts in your best interest, selecting the best hardware for the job rather than pushing the inventory they need to move.

Investigate their capabilities beyond the robot arm. Do they understand vision systems? Can they program complex logic controllers? Do they offer advanced end-of-arm tooling options? Your automation cell functions as an ecosystem. Every component must work in harmony. Your partner must possess the technical breadth to engineer the entire system, not just the movement of the robotic arm.

4. Evaluate Their Safety Expertise

Safety allows for no compromise. An unsafe robot cell is a liability that puts your employees at risk and invites severe legal consequences. Your robotics partner must demonstrate a deep, up-to-date knowledge of safety standards, including RIA/ANSI requirements.

Question them rigorously on their risk assessment process. A reputable integrator prioritizes safety from the very first design sketch. They design cells that protect human workers without strangling productivity. They understand how to implement light curtains, area scanners, and safety interlocks effectively. If a potential partner treats safety as an afterthought or a checkbox, walk away immediately. Your workforce deserves a partner who values their well-being above all else.

5. Review Their Training and Documentation Protocols

Even the most advanced automation system fails if your team cannot operate it. The transfer of knowledge determines the long-term viability of your investment. You need a partner who empowers your staff, not one who creates a dependency on their support technicians.

Demand comprehensive training programs. This includes hands-on instruction for operators, maintenance crew, and engineers. Ensure they provide clear, accessible documentation and user manuals. When the integrator leaves your facility, your team must feel confident in their ability to run, troubleshoot, and maintain the equipment. A true partner wants you to succeed independently.

6. Analyze Their Post-Installation Support Structure

Machinery requires maintenance. Software needs updates. Unforeseen issues arise. When production stops, you lose money every second. You need a partner who responds with urgency and expertise.

Scrutinize their support contract options. Do they offer 24/7 remote troubleshooting? How quickly can they deploy a technician to your site? Do they stock critical spare parts locally? Reliable support ensures your uptime remains high. You are not just buying a machine; you are buying a relationship. Make sure that the relationship includes a safety net that catches you when things go wrong.

7. Investigate Their Financial Stability

Automation projects often span months. The lifecycle of the equipment spans decades. You need a partner who will exist in five, ten, or twenty years. A financially unstable integrator poses a massive risk to your capital investment.

Do not hesitate to ask for financial references or proof of stability. A robust partner invests in their own growth, maintains a stable workforce, and manages their cash flow effectively. If they go out of business halfway through your project, you lose your deposit and valuable time. If they fold two years later, you lose your support network. Partner with a company built on a solid foundation.

8. Confirm Their Software Integration Capabilities

Hardware moves the product, but software drives the value. Modern manufacturing thrives on data. Your new robotic system must communicate seamlessly with your existing Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES).

Ask how they handle data connectivity. Can they provide real-time dashboards for OEE (Overall Equipment Effectiveness) tracking? Do they support Industry 4.0 protocols? A forward-thinking partner builds systems that provide you with actionable intelligence, allowing you to make data-driven decisions that further optimize your operations.

9. Scrutinize the Total Cost of Ownership

The lowest sticker price often leads to the highest cost in the long run. Cheap components fail faster. Poor programming causes cycle time inefficiencies. Inadequate safety designs lead to accidents.

Look beyond the initial quote. Evaluate the Total Cost of Ownership (TCO). This includes:

Energy consumption of the proposed system

Expected maintenance intervals and costs

Cost of spare parts

Potential downtime during installation

Training expenses

A premium partner might charge more upfront, but their superior engineering and reliable components save you money year over year. Invest in quality and reliability. It pays dividends.

Secure Your Future with Confidence

The decision to automate transforms your business. It signals to the market that you intend to compete at the highest level. By following these steps to choosing a robotics partner, you mitigate the risks and maximize the rewards of robotics integration. You move from uncertainty to clarity.

Do not wait for the perfect moment; create it. Selecting the right partner creates the foundation for a more efficient, safer, and more profitable future. You have the roadmap. Now, take action. Find the partner who matches your ambition and start building the future of your manufacturing operations today.