Manufacturing leaders face a critical decision in the modern industrial landscape. You must decide whether to rely on traditional manual processes or embrace the transformative power of automation. This choice determines your shop's future, its profitability, and its ability to compete in a demanding market. While manual tending served the industry for decades, the limitations of human labor now act as a brake on potential growth. Automation offers a proven path forward, but many shop owners still hesitate to pull the trigger.

Comparing manual machine tending against automated solutions reveals stark differences in performance. You need to understand exactly where automation outperforms human labor to make an informed investment. This comparison breaks down the battle between human operators and robotic systems to show you exactly which method secures the victory for your business.

Automation Increases Spindle Uptime

Your spindle only makes money when it cuts chips. Manual tending introduces unavoidable pauses in this process. Operators take breaks, attend meetings, eat lunch, and change shifts. Even the most dedicated employee cannot match the relentless pace of a robot. Machines do not require rest or downtime for personal needs. They load and unload parts with consistent speed, hour after hour.

This continuous operation keeps your CNC machines running at peak potential. You immediately eliminate the idle time that plagues manual production floors. A robot waits for the cycle to finish and swaps the part instantly. This efficiency gains you additional cycle hours every single day. Over a week, these gained hours equate to significantly higher output without adding a single extra machine to your floor.

Robots Eliminate Inconsistencies in Part Quality

Human operators introduce variables into the manufacturing process. Fatigue, distraction, and simple human error lead to inconsistencies. An operator might load a part slightly off-center or fail to clear chips adequately between cycles. These small errors compound over time, leading to scrapped parts and wasted materials.

Automation delivers absolute consistency. A robot repeats the exact same motion with precise accuracy every single time. It places the part in the fixture with the same force and alignment during the first cycle of the morning as it does during the last cycle of the night. This reliability ensures that every part meets your strict quality standards. You reduce scrap rates and guarantee that your customers receive the high-quality components they expect.

Technology Solves the Skilled Labor Shortage

Finding reliable machine operators stands as one of the biggest challenges in manufacturing today. The "skills gap" leaves machines sitting idle simply because no one is available to run them. Relying on manual tending ties your production capacity directly to your ability to hire and retain staff in a tight labor market.

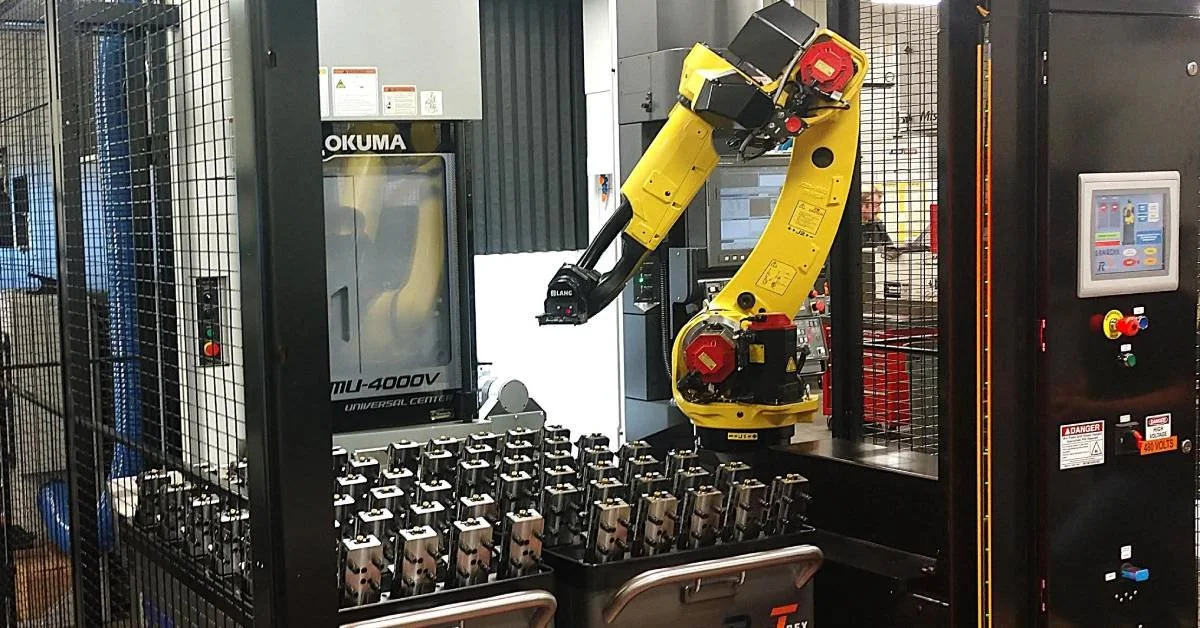

Automation breaks this dependency. By installing a robotic system, you decouple your production volume from your headcount. You no longer need to scramble to fill shifts or turn down work due to staffing shortages. The Robotrex CNC machine tending robot handles the dull, repetitive work of loading parts, allowing your existing workforce to focus on high-value tasks. This strategic shift keeps your spindles turning regardless of the current labor market conditions.

Automated Cells Improve Workplace Safety

Manual machine tending presents inherent risks. Operators reach into machines repeatedly, handle sharp parts, and perform repetitive motions that lead to strain injuries. Accidents happen, and the cost of workplace injuries impacts both your bottom line and your team's morale. Prioritizing the safety of your workforce creates a better culture and reduces liability.

Robotic cells create a physical barrier between the operator and the machining process. The robot handles the heavy lifting and repetitive movements inside the machine enclosure. Your employees remain at a safe distance, managing the process rather than performing the physical labor. This setup drastically reduces the risk of crush injuries, cuts, and repetitive strain issues. You create a safer environment that protects your most valuable asset—your people.

Machines Enable True Lights-Out Manufacturing

Manual tending limits production to the hours you have staff on-site. Running a second or third shift requires finding people willing to work difficult hours and paying them a premium. Often, machines sit dormant for twelve hours or more every day, wasting potential revenue.

Automation unlocks the potential for lights-out manufacturing. You load the storage carts before the end of the day, and the system continues to produce parts long after the lights go out. You arrive the next morning to a batch of finished components. This capability effectively doubles or triples your production capacity without increasing your payroll. Your shop makes money while you sleep, maximizing the return on your capital equipment.

Automation Stabilizes Production Costs

Manual processes involve variable costs that trend upward. Wages, benefits, and insurance premiums rise annually. Recruitment and training costs add to this burden. Predicting the exact cost per part becomes difficult when labor efficiency fluctuates day to day.

Investments in automation provide predictable, stable costs. Once you purchase and install the system, your primary expense becomes minimal maintenance and electricity. The cost to produce each part drops significantly and remains consistent. This stability allows you to bid on jobs with confidence, knowing exactly what your margins will look like. You protect your business from wage inflation and secure a competitive pricing advantage.

Automated Systems Offer Superior Scalability

Scaling a manual operation requires hiring more people. This process takes time, effort, and money. When demand spikes, you cannot simply flip a switch to add more human operators. You face delays in recruiting and training that cause you to miss opportunities.

Robotic systems offer immediate scalability. If you need more output, you run the robot longer. You utilize weekends and nights without begging staff for overtime. The modular nature of systems like RoboTrex allows you to expand capacity easily.

Rapid adaptation: You adjust to market demands instantly.

Modular growth: You add more cells as your business expands.

Flexible scheduling: You run high-volume jobs without fatigue.

This agility allows you to say "yes" to large orders and tight deadlines that manual shops simply cannot handle.

Robots Deliver a Faster Return on Investment

The upfront cost of automation often scares off potential buyers. However, you must look at the return on investment (ROI) rather than just the purchase price. Manual tending incurs costs forever. You pay for that labor every single hour, indefinitely.

Automation pays for itself. The combination of increased spindle uptime, reduced scrap, and lower labor costs generates a rapid ROI. Many shops see their investment pay off in less than two years. After that point, the increased profitability goes straight to your bottom line. You invest once to secure years of higher profits.

Take Control of Your Production Future

The battle between manual tending and Robotrex automation yields a clear winner. Automation dominates in productivity, consistency, safety, and long-term profitability. While manual processes had their time, the future belongs to those who innovate. You possess the power to transform your machine shop into a high-efficiency powerhouse.

Do not let hesitation hold you back. The technology exists today to solve your labor challenges and skyrocket your output. Embrace the certainty and reliability of robotic tending. Your competitors will eventually make the switch; ensure you lead the pack rather than follow it.