The Internet of Things (IoT) is redefining how industries operate by optimizing processes, minimizing waste, and driving productivity to new heights. By connecting devices, sensors, and systems, IoT creates a seamless network that allows you to monitor, analyze, and control industrial operations with precision and efficiency.

IoT’s role in modern industrial automation helps companies remain competitive in an increasingly digital world. Through IoT, you can revolutionize how you perform tasks, enhancing both reliability and profitability.

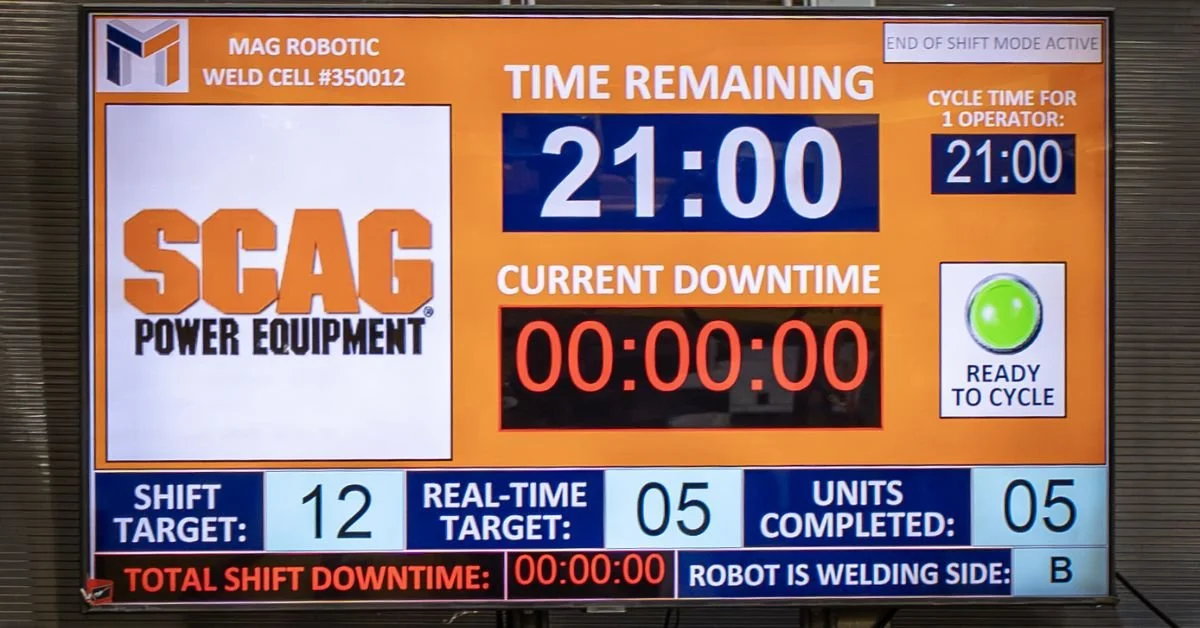

Real-Time Monitoring

IoT devices provide the ability to monitor equipment, processes, and overall operations in real time. This level of transparency enables quicker responses to disruptions, reduces downtime, and helps identify inefficiencies. Real-time monitoring also supports continuous improvement by offering detailed insights into how systems perform.

Predictive Maintenance

IoT sensors enable businesses to predict when machines are likely to require maintenance, reducing unexpected breakdowns and avoiding unplanned downtime. By continuously monitoring equipment performance and analyzing data for patterns, IoT systems can trigger timely maintenance schedules before issues arise.

This regular maintenance extends the lifespan of machinery but also minimizes repair costs and production delays. Additionally, predictive maintenance improves operational reliability by ensuring smoother workflows and greater productivity.

Data-Driven Decision-Making

IoT systems gather, process, and analyze vast amounts of real-time data from connected devices to offer valuable and actionable insights. From monitoring equipment conditions to tracking operational metrics, this data helps businesses make more informed decisions, implement effective strategies, and adapt quickly to changing conditions. By leveraging IoT-driven analytics, organizations can improve day-to-day operations and long-term planning by analyzing data to identify trends, spot inefficiencies, and optimize processes. The result is enhanced efficiency, reduced risks, and better overall performance.

Energy Efficiency

IoT-enabled devices continuously monitor energy consumption in real time, helping businesses identify inefficiencies and areas of waste. By pinpointing precisely where you can conserve energy, IoT systems enable smarter resource allocation and optimized energy usage.

Using smarter resource allocation not only reduces operational expenses but also aligns businesses with sustainability goals by minimizing their environmental footprint. Over time, improved energy efficiency can lead to significant cost savings and allow companies to meet regulatory and environmental standards more effectively.

Enhanced Safety

IoT solutions play a critical role in improving workplace safety by actively monitoring hazardous temperatures, pressures, toxic gas levels, and equipment malfunctions. Advanced sensors and automated alerts provide early warnings that allow employees and managers to address risks before accidents occur.

In addition, IoT systems can collect and analyze safety data over time, offering insights into recurring issues and enabling proactive solutions. Better insights then create safer working environments for employees, reduce liability for businesses, and foster a culture of safety across operations.

Remote Operations

With IoT technology, business owners can monitor and control systems remotely, providing unprecedented flexibility in managing operations. Remote capabilities reduce the need for constant on-site supervision, allowing managers to oversee multiple facilities in different locations from a central hub.

This ability is especially valuable in industries with harsh or hazardous working conditions, where minimizing human exposure to risks is a priority. Remote operations also make it easier to maintain productivity during emergencies or disruptions, ensuring business continuity.

Improved Quality Control

IoT tools allow for detailed monitoring of production parameters, ensuring that products meet consistent quality standards. By gathering real-time data on factors such as temperature, pressure, or material composition, IoT systems can detect anomalies and flag potential defects before they occur.

When you detect these problems, you can reduce waste, prevent recalls, and enhance customer satisfaction by delivering reliable, high-quality products. Additionally, IoT-powered quality control systems can adapt to changing production requirements, ensuring precision and consistency over time.

Supply Chain Optimization

IoT technology streamlines logistics by providing end-to-end visibility in the supply chain. Connected systems can track inventory levels, monitor shipping routes, and provide real-time updates on delivery schedules. This transparency helps businesses reduce delays, lower expenses, and ensure a more efficient flow of materials and products.

Through the integration of IoT with advanced analytics, companies can also anticipate demand fluctuations, manage stock levels more effectively, and minimize disruptions in supply chain operations.

Faster Production Cycles

IoT integration automates repetitive tasks and simplifies complex workflows, which enables manufacturers to significantly increase their production speed. By incorporating real-time data and smart automation, IoT systems ensure that processes run smoothly and efficiently. When processes run smoothly, businesses can maintain high standards of quality while meeting tight deadlines and responding quickly to market demands.

Scalability

IoT provides a scalable foundation for business growth by allowing companies to expand their systems without disrupting existing operations. As business needs evolve, IoT-enabled infrastructure can accommodate new devices, technologies, and workflows.

This connectivity makes it easier for organizations to adapt to increased demand or adopt innovative solutions. Whether you’re scaling up production, adding new facilities, or integrating additional services, IoT ensures that your business remains agile and well-prepared for future challenges.

Cost Reduction

IoT helps businesses cut costs by automating manual tasks, reducing inefficiencies, and optimizing resource usage. By streamlining operations and maximizing output, IoT enables companies to achieve more with fewer resources. Predictive maintenance minimizes expensive repairs, while enhanced quality control reduces waste and errors. Over time, these savings improve return on investment and contribute to the overall financial health of the organization.

Integration With AI and Machine Learning

IoT works seamlessly with AI and machine learning technologies to create intelligent, self-optimizing systems. With vast amounts of real-time data, IoT enables predictive analytics, anomaly detection, and automated decision-making.

For example, AI-powered IoT systems can identify patterns, predict equipment failures, and optimize production schedules without human intervention. Together, IoT, AI, and machine learning drive innovation, enhance industrial automation, and enable businesses to stay ahead of the curve.

Customization

IoT systems offer the flexibility to customize workflows to meet specific industrial needs. Whether it’s tailoring equipment settings, refining production processes, or developing unique solutions for complex challenges, IoT enables businesses to adapt to unique requirements.

This level of customization allows companies to maximize productivity, improve efficiency, and gain a competitive edge in their industry. It also ensures that operations are perfectly aligned with business goals and customer expectations.

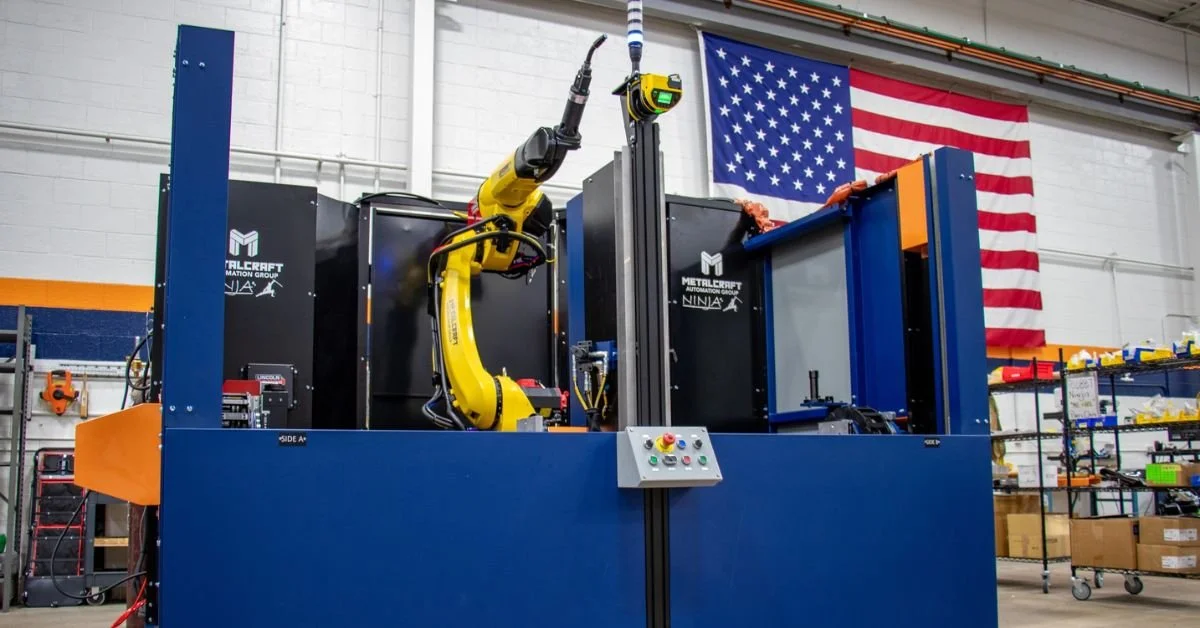

IoT’s role in modern industrial automation is to help companies innovate, adapt, and excel in today’s competitive environment. The opportunities IoT brings go beyond incremental improvements, and the best way to take advantage of industrial automation solutions is by working with Metalcraft Automation Group. We can help you adopt IoT-driven solutions and position your business as a leader in the digital age.