Integrating robots into CNC operations is no longer a concept reserved for large-scale manufacturing. Small shops today face unique challenges, from rising labor costs to tight delivery schedules, and adopting robotics can transform struggling operations into more efficient and competitive businesses. By automating repetitive tasks, increasing output, and elevating precision, CNC robots have many benefits for small shops. If you want precision, flexibility, and value, it may be time to invest in robotics.

Filling the Labor Gap

As manufacturing companies try to grow or simply keep up with demand, they have a difficult time finding skilled operators. Especially in the CNC machining environment, skilled machinists are at a premium. An investment in robotics can help fill those gaps and add many other benefits to the organization as a whole.

Boosted Productivity

Robots work tirelessly without breaks, fatigue, or loss of focus, enabling you to run longer production cycles without interruptions. Unlike people, they can operate around the clock, contributing to significantly higher outputs. This consistency not only increases productivity but also enables your shop to take on more orders, meet demanding schedules, and ultimately boost overall profitability.

Improved Consistency

Robots maintain consistent performance across all shifts, ensuring uniform results with every production run. Unlike human operators, they don’t experience fluctuations in performance due to fatigue, distractions, or mood. This consistency is especially critical in industries dependent on exceptional precision and quality, such as aerospace. With robots, you can guarantee that every product meets the same high-quality standards, minimizing errors, defects, and waste.

Faster Turnaround Times

Automated operations allow for faster task completion, enabling you to meet tight deadlines and manage demanding customer schedules with greater ease. Robots optimize workflows by minimizing idle time and expediting processes. This improvement in speed helps reduce your time-to-market, giving you a competitive advantage and ensuring customer satisfaction through timely deliveries.

Flexibility in Operations

Modern CNC robots are highly adaptable and capable of handling a wide range of tasks. Whether it’s switching between different workflows or accommodating new product designs, their versatility allows your shop to respond quickly to changes in customer demand or market trends. This flexibility makes it easier to introduce new product lines or pivot operations without major disruptions.

Scalability for Growth

Robots provide the capacity to scale your operations seamlessly as your business grows and evolves. They can handle larger production volumes without sacrificing quality, precision, or efficiency. This makes it easier to take on big projects, fulfill larger orders, and expand your customer base.

Whether you’re looking to grow regionally or globally, automation ensures your operations can meet increasing demand without overextending your resources.

Competitive Edge

Adopting CNC robotics positions your shop as an industry leader, ready to meet the demands of an ever-evolving and competitive market. Faster production times, improved quality, and the ability to scale operations give you an edge over competitors who rely on traditional methods.

Robots allow you to offer better turnaround times without sacrificing quality, helping you attract more customers and secure larger contracts. Additionally, the efficiency and reliability of automation can enable you to explore new markets, diversify your offerings, and stay ahead of industry trends.

Stronger Customer Relationships

When your shop operates with enhanced efficiency and produces dependable, high-quality results, it naturally strengthens trust with your customers. Consistently delivering superior products builds a reputation for reliability, encouraging repeat business and fostering long-term partnerships.

Additionally, the ability to scale production and maintain consistency allows you to take on challenging projects with confidence. Over time, this trust translates into stronger relationships, a loyal customer base, and a reputation as a go-to provider in your industry.

Better Use of Skilled Labor

By automating routine and repetitive tasks, you free up your skilled workers to focus on more complex, strategic, and creative aspects of your business—areas where their expertise truly shines. This shift allows your workforce to tackle tasks that require critical thinking, advanced problem-solving, or innovative designs, which can drive improvements in products and processes. It also allows employees to develop professionally by learning new skills while contributing to the growth of your shop.

Reduced Labor Costs

Automating repetitive tasks eliminates the need to hire excessive manual labor, which can be costly and prone to errors. By reducing reliance on manual workers for routine operations, you can cut down on labor costs. You can allocate these saved resources toward other areas of your business, such as innovation, marketing, or skilled roles that require human creativity and expertise.

Increased Safety

Robots are ideal for handling tasks that are hazardous, repetitive, or physically demanding, significantly reducing the risks of workplace injuries. By taking on jobs that involve exposure to dangerous materials or strenuous labor, robots create a safer, healthier work environment for your team. This proactive approach to safety not only protects employees but also reduces costs associated with workplace accidents and insurance claims.

Minimized Waste

Robots work with meticulous accuracy, drastically reducing mistakes during production. Fewer errors translate to significantly less material waste and lower costs associated with reworking defective products. This efficiency not only saves money but also supports sustainability by ensuring your team uses resources more efficiently, helping your shop reduce its environmental footprint.

Streamlined Maintenance

Automation systems often come equipped with advanced diagnostics, sensors, and monitoring tools that simplify maintenance and reduce the likelihood of unexpected downtime. These systems can detect potential issues before they cause breakdowns, allowing for proactive repairs and minimizing disruptions to your workflow.

For example, predictive maintenance capabilities can alert you to worn-out components or performance inefficiencies, giving you the chance to address problems before they escalate. This built-in reliability not only keeps your operations running smoothly but also extends the lifespan of your equipment.

Affordable Entry Points

Advancements in robotics have made automation more accessible than ever, even for smaller shops or businesses just starting out. Entry-level robotic systems now deliver impressive ROI, with lower upfront costs and shorter payback periods. These systems are user-friendly, reducing the learning curve and making integration into your existing operations straightforward.

Additionally, many manufacturers offer flexible financing options, leasing programs, or modular solutions that allow you to scale your automation efforts gradually. This affordability ensures that shops of all sizes can begin reaping the benefits of automation without breaking the bank.

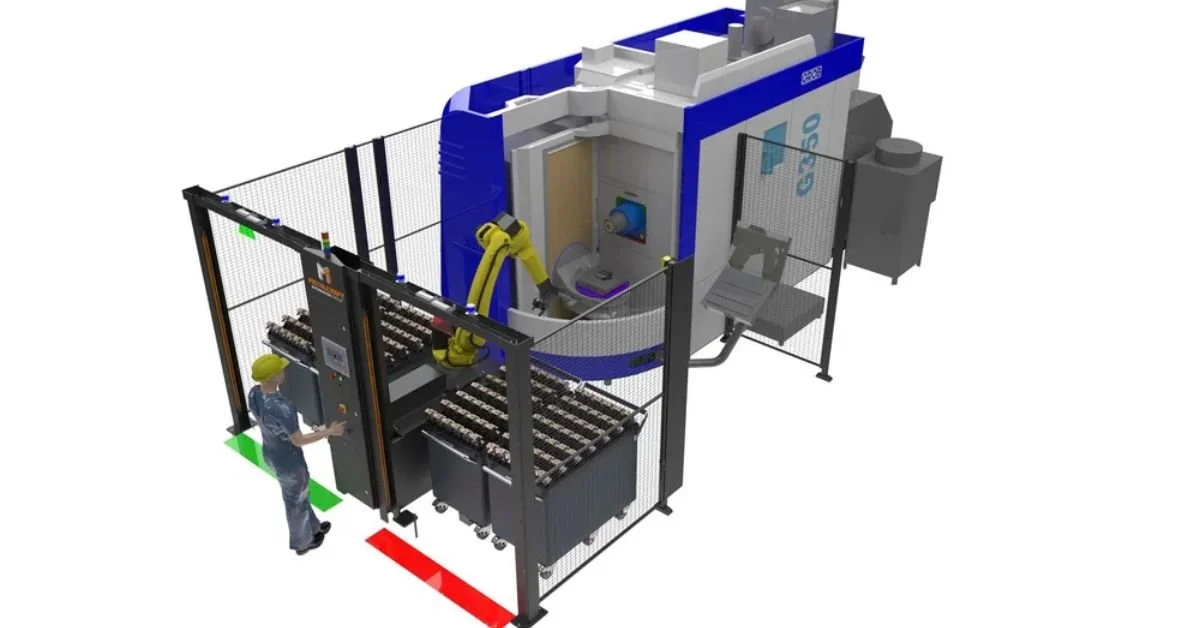

Robots in small CNC shops have numerous transformative benefits, from increased productivity and precision to reduced costs and improved workplace safety. By integrating the right RoboTrex CNC machine tending robot from us at Metalcraft Automation Group, you can elevate your shop’s capabilities, adapt to changing demands, and position yourself for sustainable growth. The time to embrace automation is now—take the leap and outperform the competition with the unmatched power of CNC robotics.