Automation has revolutionized the manufacturing industry, propelling efficiency, accuracy, and productivity to new heights. Integrating the right automation solutions is non-negotiable if you’re aiming to optimize your factory’s operations and stay ahead of the competition. These technologies streamline your business’s processes and minimize human error, reduce costs, and increase output. You must consider these top five automation solutions for factories if you want to upgrade your factory’s operations and take your industry to the next level.

Robotic Process Automation (RPA): Revolutionizing Efficiency in Your Factory

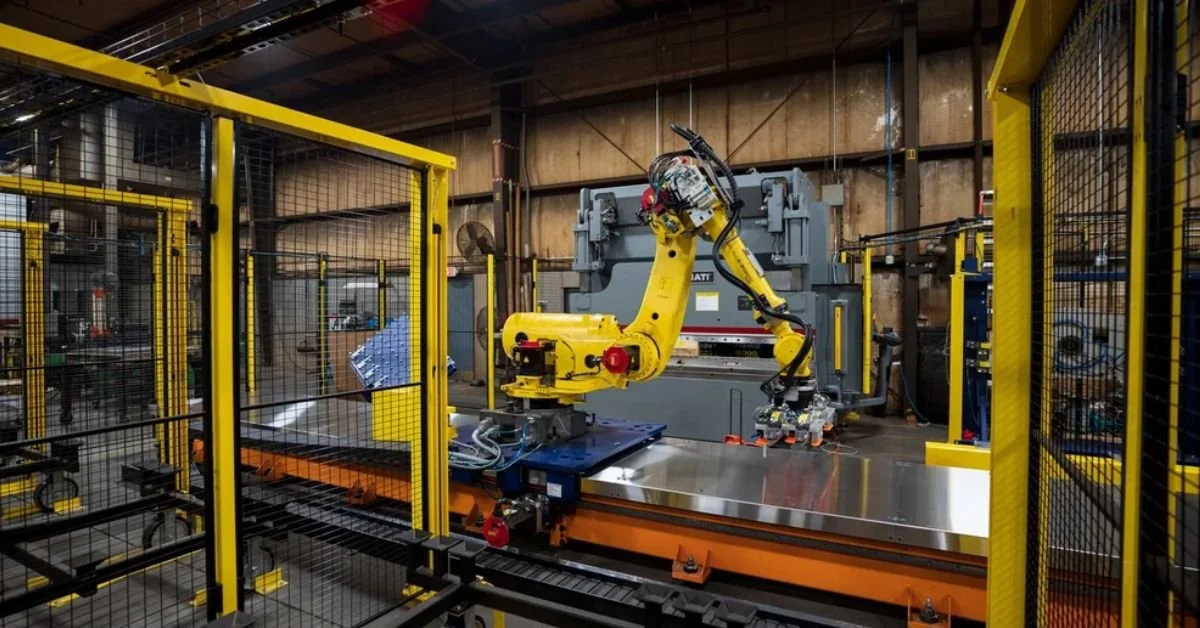

Integrating Robotic Process Automation (RPA) into your factory operations can transform productivity and efficiency. RPA involves the use of programmable robots to perform repetitive and time-consuming tasks, such as assembly, packaging, and welding, with unmatched precision and speed. RPA automates these processes in the following ways:

Reduces human error

Enhances consistency

Ensures high-quality outputs

Additionally, it allows your workforce to shift its focus toward more strategic and complex responsibilities, such as problem-solving, innovation, and process optimization. RPA proves to be a game-changer in industries where maintaining uniformity and meeting tight deadlines are crucial, delivering reliable results while maximizing cost efficiency.

Key Benefits of RPA in Manufacturing:

Robots perform tasks with extreme accuracy, significantly reducing defects and accelerating production cycles.

Automating repetitive tasks lowers labor costs and minimizes material waste.

RPA ensures uniform quality across all products, meeting stringent industry standards.

Factories can achieve higher production volumes in less time, boosting overall capacity.

Robots can handle hazardous tasks, protecting human employees from dangerous working conditions.

Better utilization of raw materials, energy, and other resources leads to more sustainable operations.

Manufacturers can streamline their operations and foster a safer, more efficient, and more sustainable production environment by leveraging these benefits.

Industrial IoT (IIoT) Systems: Connecting Machines for Smarter Operations

Industrial Internet of Things (IIoT) systems enable seamless connectivity between machines, devices, and equipment on your factory floor. You can make sure all your equipment operates in harmony when you leverage real-time monitoring and data analytics, minimizing inefficiencies and downtime. IIoT provides insights into performance metrics, helping you anticipate potential issues, such as wear-and-tear or bottlenecks, before they disrupt production.

Additionally, IIoT systems empower you to make data-driven decisions, optimize resource allocation, and maintain a competitive edge. Connected IIoT solutions help manufacturers run smarter, leaner, and more sustainable operations, whether it’s improving throughput or reducing energy consumption.

Key Benefits of IIoT in Manufacturing:

Immediate insights into equipment performance and operational statuses.

Anticipates and addresses potential issues before they cause costly downtime.

Leverages analytics to optimize resource allocation and enhance overall efficiency.

Reduces energy consumption and improves resource utilization for a leaner manufacturing process.

Embrace IIoT to ensure your manufacturing operations are resilient, efficient, and prepared for future demands.

Automated Quality Control Systems: Ensuring Flawless Products Every Time

Investing in automated quality control systems is critical for maintaining the integrity and reliability of your products. These cutting-edge systems utilize advanced technologies, such as machine vision, artificial intelligence, and deep learning, to identify defects, inconsistencies, or deviations from specifications in real-time.

Unlike human inspectors, automated systems can perform thorough quality checks at scale, ensuring every product that leaves your factory meets the highest standards. With automated quality control in place, you can confidently deliver exceptional products that build trust and satisfaction among your customers.

Key Benefits of Automated Quality Control Systems:

Minimizes human error and ensures uniform product quality.

Immediately identifies and addresses issues, preventing further production of faulty items.

Catches flaws early to save on materials and labor costs associated with fixing mistakes.

Delivers consistently high-quality products that meet or exceed customer expectations.

Collects data on defect types and frequencies to continuously refine production processes.

Automated quality control is not just about detecting errors. It’s about building a robust system that enhances every aspect of your production, from efficiency to customer trust.

Predictive Maintenance Tools: Preventing Downtime With Proactive Strategies

Predictive maintenance tools allow you to manage your factory’s equipment health proactively rather than reactively. These tools can predict when machinery is likely to fail or require maintenance by analyzing historical and real-time data.

This analytical ability means you can schedule repairs during non-critical periods, minimizing disruptions to production and avoiding costly, unexpected breakdowns. Predictive maintenance extends the lifespan of your equipment and improves operational reliability, ensuring your factory stays up and running at optimal capacity. Predictive maintenance tools help you save money and maintain seamless workflows by reducing repair expenses and unplanned downtime.

Key Benefits of Predictive Maintenance Tools:

Extends the life of your machinery with timely, data-driven maintenance.

Predicts and prevents failures, ensuring continuous operation and peak productivity.

Plans repairs strategically during non-peak hours, avoiding costly disruptions.

Maintains seamless workflows and reduces unplanned downtime, keeping your factory running at full capacity.

You can ensure your operations run smoothly, reduce expenses, and achieve long-term success by implementing these strategies.

Autonomous Guided Vehicles (AGVs): Streamlining Material Handling for Greater Efficiency

Autonomous Guided Vehicles (AGVs) are self-driving machines that move materials, goods, and raw materials across your facility with precision and safety. These vehicles drastically reduce risks associated with manual handling errors and workplace accidents, ensuring a safer environment for your team.

AGVs navigate dynamic layouts, adapt to new routes, and handle complex transportation tasks, all while maintaining a steady, organized flow of operations. AGVs optimize material handling and improve supply chain efficiency, whether it’s replenishing inventory, delivering materials to production lines, or organizing finished goods for shipping. Integrating AGVs into your operations empowers you to reduce labor costs, enhance productivity, and maintain a well-coordinated facility.

Key Benefits of AGVs in Manufacturing:

Eliminates human error in material transport, drastically reducing workplace accidents and creating a secure environment.

Ensures continuous, organized material movement throughout your facility, adapting seamlessly to changing demands.

Achieves significant cost savings and unparalleled productivity by automating repetitive and labor-intensive handling tasks.

You can transform your operations, enhance workplace safety, and achieve long-term success by leveraging these benefits.

Implementing these cutting-edge automation solutions for factories empowers your business to achieve higher productivity and efficiency, as well as overall operational success and market leadership. You are not just making an upgrade when you equip your factory with these advanced technologies—you are actively future-proofing your operations against evolving industry demands and creating a significant competitive advantage in the marketplace.

Let Metalcraft Automation Group help you future-proof your operations by embracing manufacturing automation. With us on your side, you can take decisive change in your industrial processes and unlock the full, transformative potential of automation to streamline every aspect of your workflow. Your factory’s journey toward enhanced performance and sustained growth truly starts with the strategic decisions you make today!