Technology drives innovation across industries worldwide, and CNC robotics is a prime example of this progress. By integrating robotic automation with CNC (computer numerical control) machining, businesses are changing how machine operations are performed.

This powerful combination enhances automation by maximizing efficiency and enabling companies to stay competitive in increasingly demanding global markets. Implementing CNC robotics increases productivity, reduces human error, and ensures precise, consistent results. CNC robotics are transforming machine operations by empowering manufacturers to meet evolving industry standards while maintaining high-quality production processes.

Enhanced Precision in Manufacturing

CNC robotics delivers precision that can’t be easily achieved by traditional methods. Thanks to sophisticated programming, these systems can handle even the most complex tasks with incredible accuracy, reducing material waste and boosting product quality. Whether it’s intricate milling or high-volume parts production, CNC robots consistently perform to exact specifications, ensuring superior results every time.

Reduced Downtime

Unlike human operators, robotic systems programmed for CNC operations can work tirelessly 24/7. They handle repetitive tasks with ease and require minimal intervention, significantly reducing downtime caused by human fatigue or error. With preventive maintenance systems built into many CNC robots, they also anticipate potential issues, reducing unplanned stoppages and keeping your production line running smoothly.

Optimized Workflow Efficiency

Integrating CNC robotics into your processes can eliminate production bottlenecks and improve workflow efficiency. These advanced systems seamlessly link machining, assembly, and production tasks into a cohesive process, ensuring that your operations run smoothly and without unnecessary interruptions. Over time, this enhanced efficiency allows you to take on more projects, scale your operations, and satisfy customer expectations with ease.

Greater Consistency and Quality Control

CNC systems perform tasks with exact, repeatable precision, ensuring that every component meets the same high-quality standards. Unlike manual operations, which are prone to errors and variations, CNC robotics minimizes defects and reduces waste. This reliability enhances customer satisfaction and helps establish your business as a reliable provider of superior products.

Adaptability to Complex Tasks

Modern CNC robots can tackle the most intricate and demanding tasks with ease. From creating detailed geometries to handling delicate materials, these systems can perform tasks that would be challenging, time-consuming, or impossible for manual operations. Different industries benefit from their ability to produce highly precise and custom components. This adaptability allows your business to handle both routine manufacturing needs and highly specialized projects with equal efficiency.

Improved Workplace Safety

CNC robotics significantly improves workplace safety by taking over high-risk activities that could endanger employees. Tasks such as operating heavy machinery, managing extreme temperatures, or working with sharp cutting tools are delegated to robots, reducing the risk of accidents and injuries. By removing workers from hazardous environments, your business not only provides a safer work setting but also promotes employee well-being.

Rapid Scalability

CNC robotic systems are ideal for businesses looking to scale production quickly and efficiently. Whether you need to produce small, highly customized batches or ramp up for large-scale manufacturing, these systems adapt seamlessly to changing demands. Their ability to maintain consistent quality and performance at any scale ensures that your business can respond to market trends, seasonal fluctuations, and urgent customer requests.

Minimized Labor Costs

By automating repetitive and labor-intensive tasks, CNC robotics significantly reduces the need for manual intervention, leading to lower operational costs. This greater independence allows your workforce to focus on more skilled and creative roles, such as product design, innovation, and process optimization. The result is a more engaged and productive team that drives greater value for your business. Over time, you can reinvest the cost savings from automation into other areas of growth, such as research and development.

Real-Time Monitoring and Analytics

Modern CNC robotic systems have powerful data-gathering tools that enable real-time monitoring and analytics. These features allow you to track performance metrics, identify inefficiencies, and implement preventive maintenance before issues arise.

With access to actionable insights, you can optimize operations, reduce downtime, and ensure your systems are always running at peak performance. This level of oversight not only improves day-to-day operations but also supports long-term strategic planning.

More Energy Efficiency

CNC robotics contributes to more sustainable manufacturing processes by conserving resources and minimizing environmental impact. The precision of these systems reduces material waste and streamlines operations to save energy. Additionally, their efficiency often leads to significant cost savings in energy consumption.

By aligning your business with sustainable practices, you can lower your carbon footprint while enhancing your brand’s reputation for environmental responsibility—an increasingly important factor for today’s customers and stakeholders.

Expanded Customization

One of the standout features of CNC robotics is its ability to handle customization with ease. You can program these systems to accommodate diverse customer needs, from unique product designs to small-batch production runs. Whether you’re creating personalized items or meeting niche market demands, CNC robotics ensures that efficiency and precision are never compromised.

Shortened Production Cycles

Speed is a critical factor in today’s competitive manufacturing landscape, and CNC robotics delivers exceptional results in this area. These systems complete tasks faster than manual processes while maintaining consistent quality.

This shortened production cycle better allows you to meet tight deadlines, reduce lead times, and respond to urgent customer demands more effectively. These new timelines make it easier for your business to improve its overall agility and customer satisfaction, giving you an edge over competitors who rely on slower, traditional methods.

Seamless Integration With Industry 4.0 Technologies

CNC robotics work in harmony with cutting-edge Industry 4.0 technologies such as IoT, AI, and machine learning. These integrations enable smarter, more adaptive manufacturing processes by collecting and analyzing data in real time.

For example, IoT sensors can provide instant feedback on machine performance, while AI algorithms optimize production schedules. By adopting these advanced technologies, your business can achieve greater automation, innovation, and flexibility, positioning you as a leader in the next wave of industrial transformation.

Future-Proofing Your Operations

Investing in CNC robotics is a strategic move to future-proof your business in an era of rapid technological advancements. These systems grow with your needs by adapting to new challenges, market demands, and opportunities.

When you stay ahead of the curve, you ensure that your operations remain agile, innovative, and competitive in an ever-evolving industrial landscape. CNC robotics prepares your business for future success and reinforces your commitment to excellence and innovation.

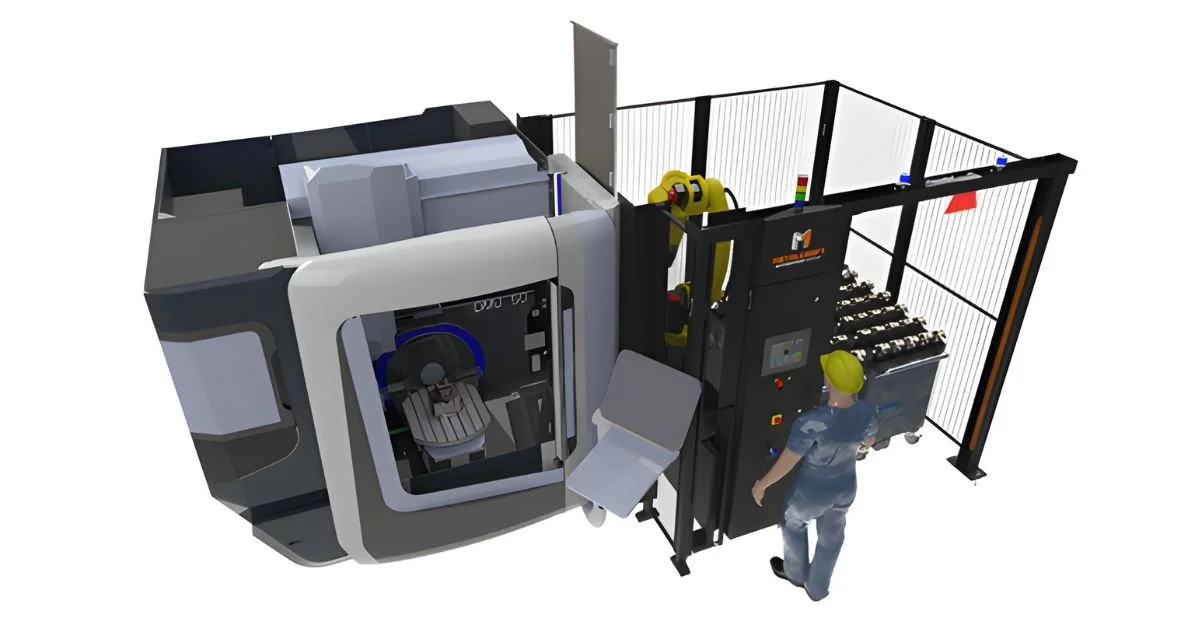

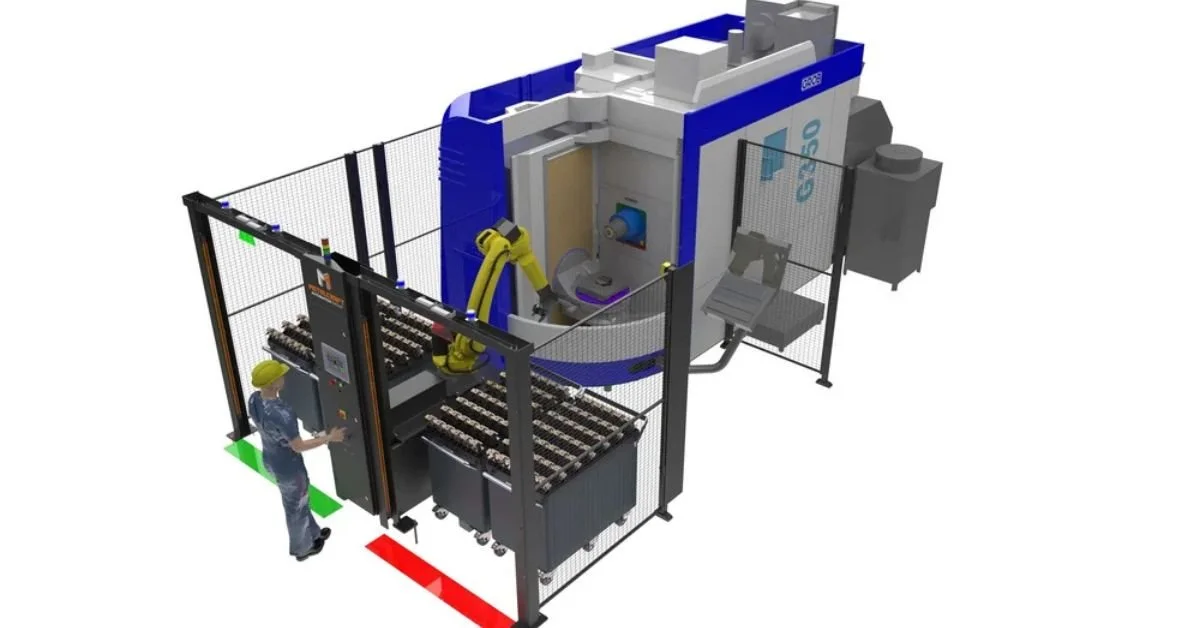

CNC robotics are transforming machine operations by allowing businesses to enhance productivity, safety, and efficiency across the board. With CNC robotics and Metalcraft Automation Group’s RoboTrex CNC machine tending robot, you can focus on scaling your business, meeting customer demands, and driving innovation—all while staying ahead in a rapidly evolving global market.