Industrial automation is no longer a distant concept; it is the definitive path to achieving unparalleled productivity and a powerful competitive edge. Businesses that embrace automation unlock significant gains in efficiency, quality, and profitability. The decision to invest is not a matter of if, but when. Delaying this critical step means falling behind competitors who are already capitalizing on these powerful technologies.

Analyzing the cost-benefit of industrial automation reveals a clear and compelling business case. The initial investment pays for itself through substantial short-term and long-term returns, including reduced operational expenses, enhanced production capacity, and improved product consistency.

This exploration details the tangible advantages and financial considerations of implementing industrial automation. By understanding both sides of the equation, you can make a confident, strategic decision that propels your business forward.

What Are the Direct Financial Gains?

Industrial automation drives substantial financial returns by directly targeting key operational costs. Automated systems operate with precision and speed, which reduces labor expenses tied to manual tasks. These systems work around the clock without fatigue, eliminating the need for multiple shifts and overtime pay. This continuous operation maximizes output while minimizing payroll costs, creating a direct and immediate impact on your bottom line.

Furthermore, automation minimizes waste by ensuring consistent, high-quality production. Automated machinery executes tasks with exactness, which drastically reduces material scrap and rework expenses. Every component produced meets precise specifications, leading to fewer defects and lower associated costs. This efficiency translates into significant savings on raw materials and improves overall profitability.

How Does Automation Reduce Operational Expenses?

Automation streamlines operations by reducing costs beyond direct labor. One of the most significant savings comes from lower energy consumption. Modern automated systems and robots are engineered for energy efficiency, using less power than older, manually operated machinery. Smart sensors and control systems also optimize energy use by powering down equipment when not in use, which contributes to lower utility bills.

Maintenance costs also decrease with automation. Predictive maintenance technologies, powered by AI and sensors, monitor equipment health in real time. These systems identify potential issues before they lead to catastrophic failures, allowing you to schedule repairs proactively. This approach prevents costly unplanned downtime and extends the lifespan of your machinery, which reduces long-term capital expenditures.

How Does Automation Improve Productivity and Throughput?

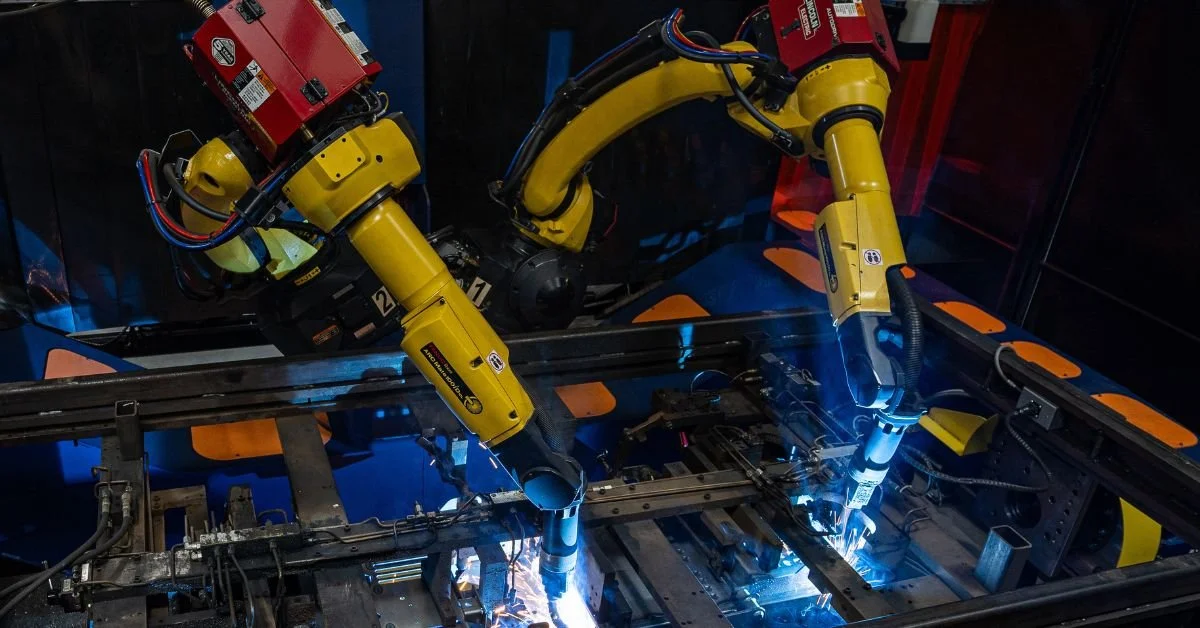

Automated systems dramatically increase production speed and volume. Robots and automated machinery perform tasks faster than human workers and can operate 24/7 without breaks. This continuous workflow eliminates bottlenecks and accelerates the entire production cycle, from raw material intake to final product packaging. The result is a significant boost in throughput, enabling your business to meet higher demand and take on larger orders with confidence.

Integrating industrial automation solutions also enhances overall process efficiency. Automated guided vehicles and conveyor systems move materials seamlessly between workstations, which minimizes transit time and keeps production flowing smoothly. By optimizing the entire manufacturing process, your organization can produce more goods in less time, directly increasing revenue potential.

What Is the Impact on Product Quality and Consistency?

Automation is the key to achieving superior product quality and consistency. Automated systems perform repetitive tasks with a level of precision that is impossible for humans to sustain. Each product is manufactured to the exact same specifications, which eliminates variations and ensures a uniform standard of quality across all production runs. This consistency builds brand reputation and customer trust.

By minimizing human error, automation also reduces the rate of defects. Automated inspection systems use high-resolution cameras and sensors to identify flaws that the human eye might miss. This rigorous quality control process ensures that only flawless products reach the market. Fewer defects mean less waste, fewer customer returns, and a stronger bottom line.

How Does Automation Enhance Workplace Safety?

Automating dangerous and physically demanding tasks creates a safer work environment for your employees. Robots can handle jobs that involve hazardous materials, extreme temperatures, or heavy lifting, which removes workers from harm’s way. This reduces the risk of workplace accidents and injuries, leading to lower workers' compensation claims and a more secure workforce.

A safer workplace also boosts employee morale and retention. When employees feel that their well-being is a priority, they are more engaged and loyal. By automating the most strenuous and risky tasks, you empower your team to focus on higher-value activities that require human intellect and creativity, creating a more fulfilling work experience.

What Is the Initial Investment Cost?

The initial cost of automation includes several components. The primary expense is the purchase of hardware, such as robots, sensors, and control systems. Software licensing and development fees are also part of the upfront investment. Additionally, you must account for installation and integration costs, which involve configuring the new systems to work with your existing infrastructure. Though significant, you should view this investment as a strategic expenditure that unlocks long-term value.

How Do You Calculate the Return on Investment?

To calculate the ROI of automation, you must compare the total investment cost to the financial gains it generates over time. Start by quantifying the savings from reduced labor costs, lower material waste, and decreased energy consumption. Next, factor in the increased revenue from higher productivity and improved product quality. By subtracting the initial investment from these total gains, you can determine the net financial benefit and calculate your ROI.

What Are the Hidden Costs to Consider?

Beyond the initial purchase, there are other costs to consider. Employee training is important to ensure your team can operate and maintain the new automated systems effectively. Ongoing maintenance and occasional software updates also contribute to the total cost of ownership. Factoring these expenses into your financial analysis provides a more accurate and realistic picture of the long-term investment.

How Does Automation Provide a Competitive Advantage?

Automation enables your business to respond to market changes with greater speed and flexibility. Automated production lines can be quickly reprogrammed to accommodate new product designs or adjust output levels. This agility allows you to introduce new products faster and adapt to shifting consumer demands, giving you a distinct advantage over less nimble competitors.

Seize Your Competitive Edge

The cost-benefit analysis is undeniable: industrial automation delivers a powerful return on investment by cutting costs, boosting productivity, and enhancing quality. Businesses that implement these solutions position themselves as industry leaders, capable of navigating market challenges with agility and confidence. The strategic benefits of improved safety, increased throughput, and superior consistency create a compounding advantage that secures long-term growth.

Do not wait for the competition to dictate your future. Take decisive action to integrate automation into your operations and unlock your business’s full potential. The path to greater efficiency and profitability is clear. Embrace the power of automation and build a stronger, more competitive enterprise.