Lean manufacturing focuses on one core idea: delivering more value to customers while using fewer resources. Manufacturers that embrace lean principles work to eliminate waste, reduce variability, and create predictable, efficient workflows. Automation often plays an important role in making that possible, especially in machining environments where labor availability, consistency, and uptime directly affect output.

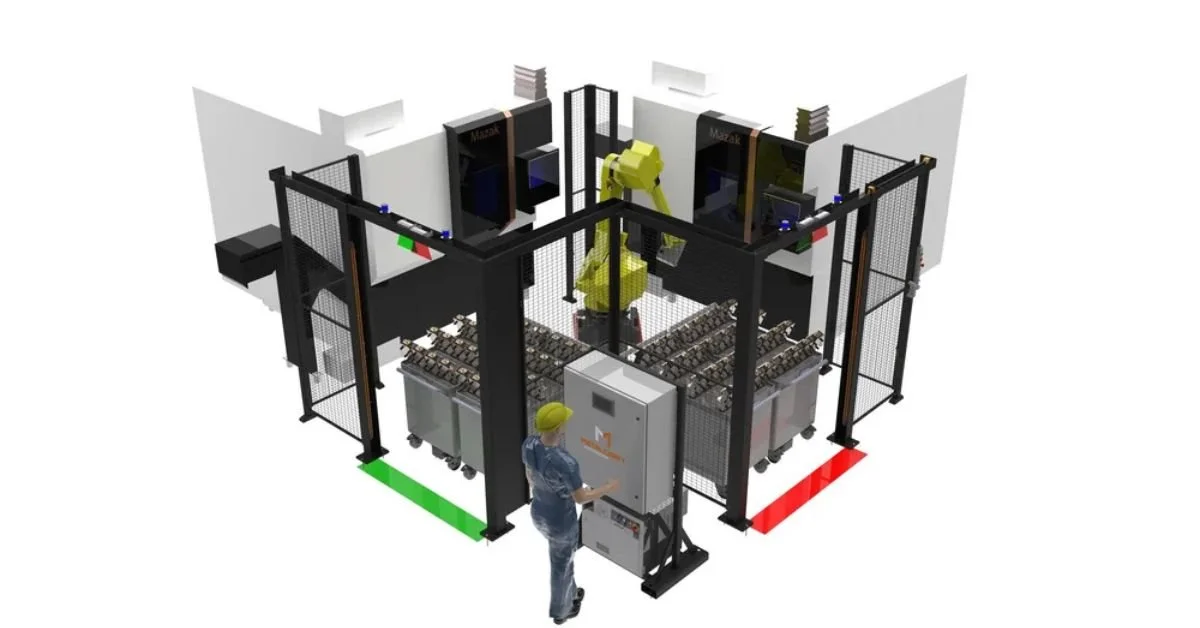

RoboTrex supports lean manufacturing goals by helping machine shops and manufacturers streamline CNC operations, improve utilization, and stabilize production without adding unnecessary complexity. When implemented correctly, automation like RoboTrex aligns closely with lean thinking rather than working against it.

Below, we’ll break down how RoboTrex supports lean manufacturing principles in practical, measurable ways.

Understanding Lean Manufacturing in CNC Environments

Lean manufacturing aims to remove non-value-added activities from production. In CNC machining, common sources of waste include idle machines, inconsistent cycle times, excess work-in-process, and unnecessary operator movement.

Lean-focused manufacturers prioritize:

Continuous flow

Standardized work

Predictable output

Efficient use of labor and equipment

CNC automation fits naturally into these priorities when it improves flow and reliability rather than adding bottlenecks or complexity.

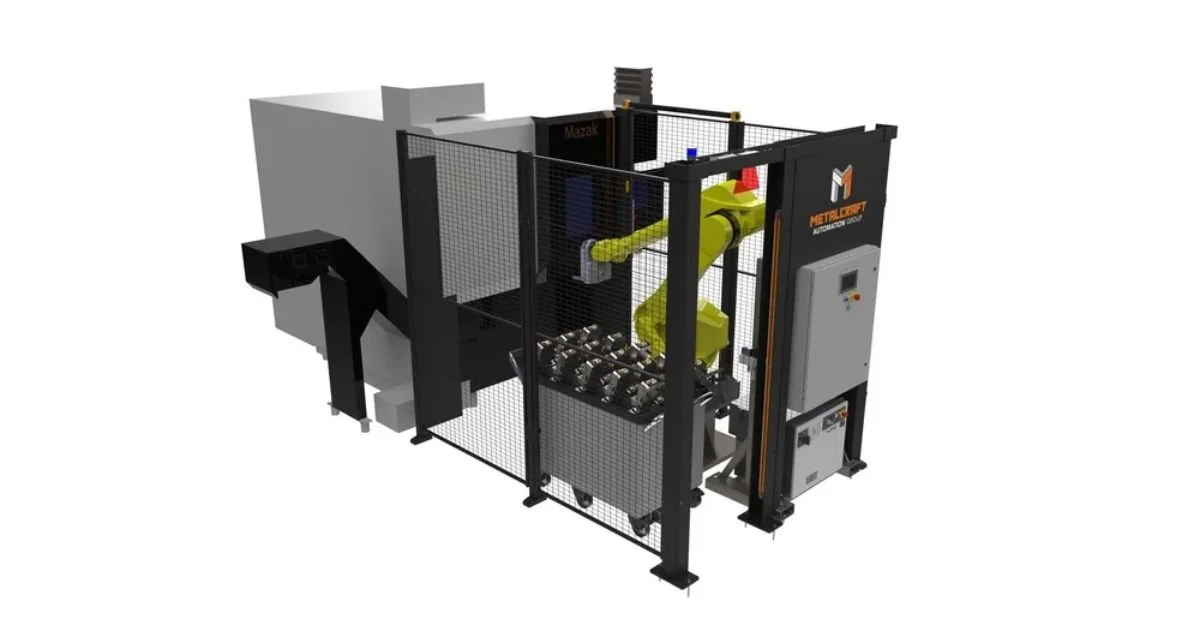

Reducing Non-value-added Cost

Designed for maximum ROI (return on investment), the RoboTrex system integrates flawlessly with LANG-Technik-USA’s suite of precision products, including Zero-Point Plates, Self-Centering Vises, and industry-leading Makro-Grip Stamping technology. By implementing Zero-Point Plates, shops can drastically reduce downtime, transitioning from prototype development to full-scale automation in minutes rather than hours.

The inclusion of Self-Centering Vises further accelerates throughput by simplifying setup and streamlining off-line programming. To get the most out of your machines, Makro-Grip Stamping eliminates the "hidden costs" of material prep. By moving squaring and dovetailing tasks to an off-line bench-top press, you reclaim valuable CNC spindle time—turning minutes of non-value-added machining into seconds of simple material prep. This is more than a toolset; it is a strategic leap toward continuous improvement and operational excellence.

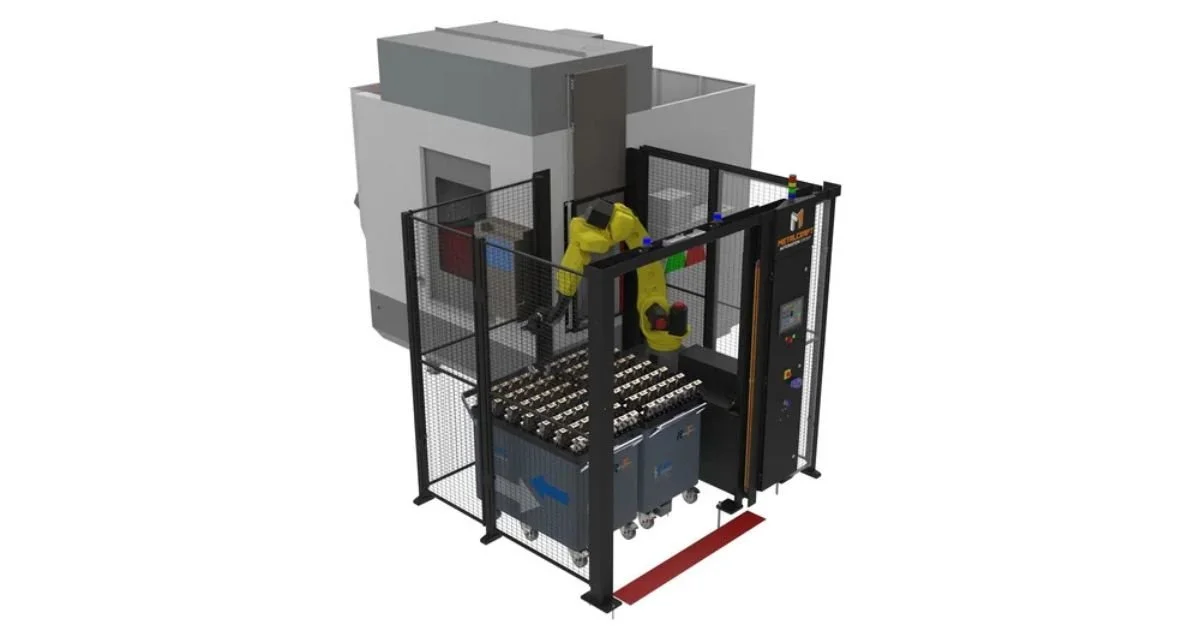

Reducing Machine Downtime Through Automated Tending

Machine downtime represents one of the most visible forms of waste in a machining operation. Every minute a CNC machine waits for an operator to load or unload parts reduces overall equipment effectiveness.

RoboTrex minimizes this waste by keeping machines running consistently throughout the shift. Automated tending ensures that machines receive parts on time and unload completed components without delays caused by operator availability or multitasking.

As uptime increases, manufacturers gain better control over production schedules and reduce the need for overtime or expedited workflows.

Supporting Continuous Flow on the Shop Floor

Lean manufacturing emphasizes continuous flow instead of stop-and-go production. Manual CNC tending often interrupts flow because operators balance multiple machines or tasks at once.

RoboTrex supports continuous flow by maintaining steady, repeatable machine cycles. Once programmed and integrated, the system feeds parts at consistent intervals, allowing machining operations to progress smoothly without unexpected interruptions.

This stability helps downstream processes plan more accurately and reduces bottlenecks across the production line.

Standardizing CNC Operations for Predictable Output

Standardized work serves as a cornerstone of lean manufacturing. Variation in how operators load parts, start cycles, or handle completed components can lead to inconsistent results.

RoboTrex standardizes CNC machine tending by performing the same motions, sequences, and handling routines every cycle. This consistency reduces variation and improves process reliability, which directly supports lean goals related to quality and repeatability.

Standardization also simplifies process documentation and makes it easier to identify opportunities for continuous improvement.

Improving Labor Utilization Without Eliminating Jobs

Lean manufacturing focuses on using labor more effectively, not removing people from the process altogether. In many machine shops, skilled operators spend too much time on repetitive loading tasks instead of higher-value work.

RoboTrex allows manufacturers to reassign operators to:

Programming and setup

Quality checks

Process optimization

Preventive maintenance

By shifting labor toward tasks that require human judgment and experience, companies strengthen their operations while maintaining lean efficiency.

Reducing Work-in-Process Inventory

Excess work-in-process (WIP) ties up capital and hides inefficiencies. Lean environments aim to keep WIP levels low while maintaining steady throughput.

RoboTrex supports lower WIP by enabling predictable production rates. When CNC machines operate at known, repeatable speeds, planners can better align upstream and downstream processes.

This predictability reduces the temptation to overproduce “just in case” and helps manufacturers operate closer to true demand-driven production.

Enhancing Quality Through Consistent Part Handling

Quality issues create waste in the form of rework, scrap, and inspection delays. Manual handling introduces variation that can affect part placement, clamping, and surface condition.

RoboTrex improves quality by handling parts consistently from cycle to cycle. The system loads parts with precise positioning and removes them without unnecessary contact or force.

This consistency supports lean quality goals by reducing defects and allowing quality teams to focus on process improvement instead of damage control.

Supporting Lights-Out and Extended Production

Lean manufacturing encourages maximizing the value of existing assets before adding new ones. One way to do that involves extending production hours without increasing labor costs.

RoboTrex enables unattended or lightly attended operation during evenings, nights, or weekends. By running machines beyond traditional shifts, manufacturers increase output without expanding floor space or staffing.

Extended production also smooths demand fluctuations and helps maintain steady flow during peak periods.

Simplifying Lean Cell Design

Lean layouts often rely on compact cells that reduce travel distance and improve visibility. Large, complex automation systems can sometimes conflict with this approach.

RoboTrex supports lean cell design by integrating directly with CNC machines in a controlled footprint. The system fits into existing workflows without requiring major facility changes.

This flexibility allows manufacturers to apply lean principles like cellular manufacturing while still benefiting from automation.

Enabling Data-Driven Continuous Improvement

Continuous improvement depends on accurate data. Inconsistent manual processes make it difficult to measure true performance.

RoboTrex generates consistent cycle data that teams can analyze to identify improvement opportunities. Reliable machine utilization metrics, cycle times, and uptime data help lean teams make informed decisions.

With clear performance baselines, manufacturers can test changes, measure results, and refine processes with confidence.

Aligning Automation With Lean Culture

Lean manufacturing succeeds when technology supports people rather than replacing problem-solving with complexity. RoboTrex aligns with lean culture by remaining practical, focused, and purpose-driven.

The Robotrex CNC machine tending robot fits into lean environments because it solves specific operational challenges without introducing unnecessary features or complexity. Teams can focus on value creation instead of managing the automation itself. This alignment helps ensure long-term adoption and ongoing improvement.

Supporting Scalability Without Disrupting Lean Systems

Lean manufacturers often grow incrementally, expanding capacity as demand increases. Automation that requires major redesigns can disrupt established lean systems.

RoboTrex supports scalability by allowing manufacturers to add automation strategically. Shops can deploy systems where they create the most value and expand over time without reworking the entire production layout.

This approach protects lean gains while supporting long-term growth.

Strengthening Safety While Improving Efficiency

Safety and lean manufacturing go hand in hand. Unsafe conditions create waste through injuries, downtime, and training disruptions.

RoboTrex reduces repetitive manual handling and minimizes operator exposure to moving machinery. Improved safety leads to fewer interruptions and more stable operations.

When teams feel safe and supported, they can focus on improving processes instead of reacting to preventable incidents.

Reinforcing Lean Goals Through Practical Automation

Lean manufacturing does not reject automation. Instead, it encourages automation that directly supports flow, quality, and efficiency.

RoboTrex reinforces lean goals by:

Reducing downtime and variability

Improving labor utilization

Supporting predictable, continuous flow

Enhancing quality and safety

By addressing real-world challenges in CNC environments, RoboTrex helps manufacturers move closer to lean ideals without sacrificing flexibility or control.

Final Thoughts on RoboTrex and Lean Manufacturing

Lean manufacturing requires discipline, consistency, and a commitment to continuous improvement. CNC automation plays an important role when it strengthens processes rather than complicating them.

RoboTrex supports lean manufacturing goals by delivering reliable machine tending that improves uptime, quality, and labor efficiency. When manufacturers align automation with lean principles, they create systems that work better today and adapt more easily tomorrow.

For shops looking to reduce waste, stabilize production, and get more value from existing equipment, RoboTrex offers a practical path forward that fits naturally within a lean manufacturing strategy.