Human error is an unavoidable part of any manual manufacturing process. Even with the most skilled and dedicated workforce, mistakes can happen. These errors, ranging from minor miscalculations to significant assembly flaws, can lead to wasted materials, increased costs, and damaged reputations. This is where industrial automation comes in, offering a powerful solution to minimize production errors and elevate your entire operation.

By integrating automated systems, you can achieve a level of accuracy and consistency that is simply unattainable through manual labor alone. Automation streamlines workflows, enhances quality control, and ultimately drives greater efficiency and profitability. Let's explore how embracing automation can transform your production line and drastically reduce costly production errors.

The High Cost of Manual Errors

In manufacturing, even the smallest mistake can have a ripple effect that will affect everything further down the line. A misaligned component, an incorrect measurement, or a poorly executed weld can compromise the integrity of the final product. These errors lead to several challenges for businesses.

First, there's the direct financial impact. Defective products must be reworked or scrapped, consuming more raw materials and labor hours. Second, production slowdowns occur as teams stop in order to identify and correct mistakes. This leads to disrupted schedules and delayed shipments. Finally, consistent quality issues can erode customer trust and damage your brand's standing in the market. Overcoming these challenges requires a shift from reactive problem-solving to proactive error prevention.

Enhancing Precision with Robotic Systems

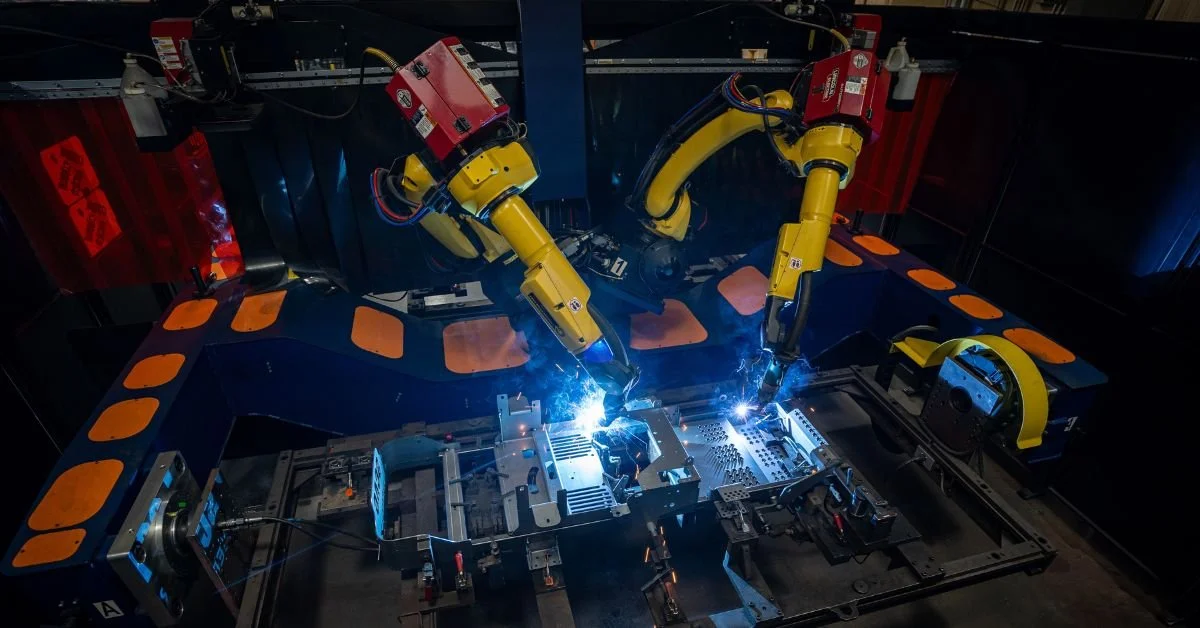

One of the most significant advantages of automation is its ability to perform tasks with incredible precision, time after time. Robotic systems are programmed to execute specific movements and processes with tolerances that far exceed human capabilities.

This level of precision not only reduces variability but also minimizes waste, ensuring optimal use of resources. For example, in manufacturing, automated systems can consistently produce components to exact specifications, reducing the likelihood of defects and the need for costly rework. Accuracy such as this supports compliance with stringent industry standards, which is critical in sectors like aerospace, healthcare, and electronics. By relying on robotic systems, businesses can achieve higher consistency in quality while significantly lowering operational risks associated with human error.

Unmatched Consistency and Repeatability

Unlike human workers who can experience fatigue or distraction, robots perform their programmed tasks with the same accuracy on the first cycle as they do on the ten-thousandth. This is especially critical in metalworking for tasks like:

Welding: Automated welding systems deliver consistent, high-quality welds, reducing structural weaknesses and improving the durability of the final product.

Cutting and Machining: CNC machines and robotic arms can cut, drill, and shape metal parts to exact specifications, eliminating variations between pieces.

Assembly: Robots can handle and place components with a level of precision that minimizes fitment issues and ensures every product is assembled correctly.

By taking the variability out of these critical processes, automation helps to make sure that every product coming off your line meets the same high-quality standard.

Streamlining Workflows for Greater Efficiency

Automation isn't just about replacing manual tasks; it's about re-engineering your entire workflow for maximum efficiency. An integrated automation setup connects different stages of the production process, creating a seamless flow that reduces bottlenecks and minimizes opportunities for error. The fewer errors you need to deal with, the more efficient your production line becomes.

The Power of an Integrated System

Imagine a production line where raw materials are loaded, moved, processed, and inspected without manual intervention. This is the reality of a fully integrated automation solution. Automated guided vehicles (AGVs) can transport materials between workstations, robotic arms can load and unload machines, and conveyor systems can move finished parts to the next stage.

This level of integration does more than just speed up production. It creates a highly organized and predictable environment where you can optimize every step of the process. Through implementing industrial automation solutions, you free up your skilled employees to focus on more complex, value-added activities like quality assurance, system monitoring, and process improvement. This makes your operation more efficient and also creates a more engaging and rewarding work environment for your team.

Improving Quality Control Through Automation

Automation also plays a crucial role in modern quality control. Automated inspection systems can identify defects that might be missed by the human eye, ensuring that faulty products are caught early in the process before they move further down the line.

Advanced Inspection Technologies

Modern automation solutions can incorporate advanced technologies like:

Machine Vision: High-resolution cameras and sophisticated software can inspect parts for surface defects, incorrect dimensions, or missing components at high speeds.

Sensors: Various sensors can be integrated to check for proper torque, pressure, or temperature during assembly, flagging any deviations from the norm.

Data Collection: Automated systems collect vast amounts of data from every stage of production. This data can be analyzed to identify trends, predict potential issues, and make data-driven decisions for continuous improvement.

By building quality checks directly into the automated process, you move from a reactive "inspect and reject" model to a proactive one that prevents errors from happening in the first place.

Your Partner in Precision

Making the transition to automation can feel like a significant undertaking, but you don't have to do it alone. At Metalcraft Automation Group, our mission is to provide proven, reliable, and effective automation solutions that help you overcome your biggest manufacturing challenges and reduce production errors. We specialize in delivering cutting-edge industrial automation tailored to the unique demands of the metalworking industry.

With years of expertise and a commitment to innovation, we partner with you to design and implement customized solutions that meet your specific business goals. From state-of-the-art robotic systems to fully integrated manufacturing setups, we deliver the reliability, scalability, and expertise your operation needs to stay ahead. By automating repetitive tasks and optimizing your workflows, our solutions ensure your production line experiences unparalleled consistency, reduced errors, and superior output quality.

Let us help you give your company the competitive advantage it deserves.

Ready to reduce production errors and redefine efficiency in your facility? Contact Metalcraft Automation Group today to learn how our industrial automation solutions can improve your manufacturing processes and help you realize your vision for the future.