Energy efficiency is a vital part of modern industrial operations. With rising energy costs and environmental concerns, you need solutions that streamline processes while reducing waste. Industrial automation provides the tools and technology to increase energy savings across your facility. By adopting industrial automation solutions, you can help your business save energy and reduce costs!

There are some kinds of building-level automation around HVAC units and lighting, but automation around your equipment and processes can also dramatically save you energy. If you’re interested in saving your industry more energy, embracing all kinds of automation is a must.

Optimizing Energy Usage

Automation systems continuously monitor and analyze energy usage patterns across operations, both for equipment and for the building you operate in. By identifying periods of low activity or downtime, they adjust energy consumption accordingly, ensuring minimal waste. This precision cuts unnecessary energy expenses while also contributing to more sustainable operations by reducing the overall carbon footprint.

Reducing Human Error

Manual processes, whether centering on equipment or building maintenance, are prone to mistakes, which can lead to energy inefficiencies, such as leaving equipment running or mismanaging systems. Automated systems eliminate these errors by taking over repetitive tasks, ensuring energy is only used when and where it’s needed while also increasing overall operational accuracy and reliability.

Implementing Smart Sensors

Smart sensors serve as the foundation of energy-efficient automation. These advanced devices monitor equipment, processes, and environmental conditions in real time, enabling building systems to adjust energy usage dynamically.

For example, sensors can detect when machinery is running at minimal capacity and either reduce the energy input or temporarily shut it down to prevent unnecessary power consumption. This adaptive approach not only maximizes resource efficiency but also lowers operational costs and extends the equipment’s lifespan. In addition, smart sensors help identify patterns in energy usage, offering valuable insights that can guide strategic decisions to enhance efficiency further.

Demand-Driven Production

Equipment automation enables production systems to closely align with real-time market demands, reducing energy waste and improving efficiency. Machines and systems operate only when there is a specific need, scaling up or down instantly to match requirements. This demand-driven approach:

• Minimizes overproduction

• Conserves energy

• Decreases wear and tear on equipment

For instance, in industries like manufacturing or agriculture, automated systems can track customer demand or seasonal trends, adjusting production schedules accordingly to avoid the overuse of energy and raw materials.

Automating Lighting Systems

Lighting in industrial facilities often accounts for a significant portion of energy consumption, particularly in large spaces such as warehouses, factories, and distribution centers. Building automation systems incorporate motion-activated sensors, daylight-responsive dimmers, and schedule-based controls to minimize energy waste.

For example, lights can automatically switch off in unoccupied areas or dim during daylight hours when natural light is sufficient. This ability reduces unnecessary energy use and significantly cuts lighting-related energy costs.

Improving Motor Efficiency

Motors are among the largest consumers of energy in industrial environments, powering everything from conveyor belts to ventilation systems. Automated equipment systems can enhance motor efficiency by optimizing speed and energy input based on real-time workload demands. For example, during periods of lower demand, motors can operate at reduced speeds, consuming far less energy than traditional motors that run at full capacity, regardless of the workload.

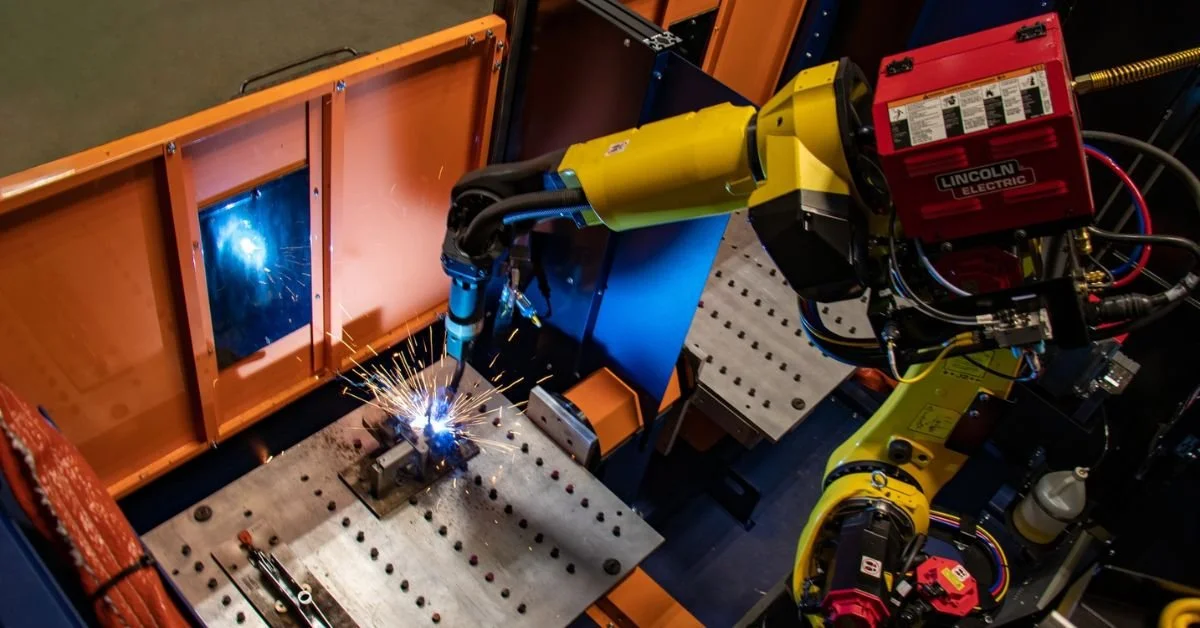

Streamlining Processes

Automation eliminates inefficiencies throughout production workflows by optimizing every step of the process. Systems ranging from building controls to smaller equipment automated systems ensure that you use resources such as electricity, fuel, and raw materials as efficiently as possible, minimizing waste.

For example, automated assembly lines can synchronize tasks to avoid bottlenecks, ensuring smooth operation and reducing energy usage. By identifying and addressing inefficiencies, automation boosts productivity, lowers energy costs, and reduces the environmental footprint.

Enhancing Predictive Maintenance

Predictive maintenance powered by automation helps businesses avoid energy spikes caused by malfunctioning equipment or worn-out components. Automated monitoring systems continuously track the performance of machinery, identifying potential issues such as:

• Overheating motors

• Excessive vibrations

• Declining efficiency

By addressing these problems early, facilities can avoid unplanned downtime and minimize energy waste. For example, replacing a failing motor before it overheats helps prevent excess energy consumption and costly repairs. Predictive maintenance also ensures equipment operates at peak efficiency, which is crucial for reducing long-term energy costs.

Integrating Energy Storage Solutions

Equipment automation seamlessly integrates with energy storage systems, such as batteries, to optimize energy distribution and usage. Excess energy generated during periods of peak efficiency is easy to store for later use, reducing reliance on external power sources and cutting overall energy costs.

This excess energy is especially beneficial for facilities using renewable energy systems like solar panels or wind turbines, which often produce intermittent power. Automation ensures that you use stored energy efficiently during periods of high demand.

Improving Heating and Cooling Systems

Heating, ventilation, and air conditioning (HVAC) systems are major energy consumers in industrial facilities, especially in climates with extreme temperatures. Automated building HVAC systems optimize temperature management by adjusting settings based on occupancy, time of day, and environmental conditions.

For example, automated controls can scale back heating or cooling during off-peak hours or when specific areas of a facility are empty. This scalability reduces unnecessary energy expenditure and helps maintain a comfortable working environment while keeping costs under control.

Supporting Renewable Energy Integration

Automation plays a crucial role in integrating renewable energy sources like solar and wind into industrial operations. These systems continuously monitor energy production and consumption, dynamically adjusting usage to maximize efficiency.

Minimizing Waste in Processing

Industrial processes often generate waste in the form of excess materials, inefficient energy use, and unnecessary byproducts. Efficient equipment automation helps minimize this waste by closely monitoring inputs and outputs at every stage of production. For instance, automated systems can measure precise quantities of raw materials needed for each task, reducing overuse and ensuring your team uses resources efficiently.

Creating Scalable Solutions

As businesses grow, their unique energy needs evolve. Automation systems are scalable, adapting to changing operational requirements with ease. Whether expanding production lines, increasing equipment usage, or incorporating new technologies, automated systems ensure energy consumption scales efficiently and aligns with actual business needs.

This adaptability allows businesses to grow without facing skyrocketing energy costs or compromising operational efficiency, supporting long-term success and sustainability. Scalability also makes it easier to integrate future innovations, ensuring the business stays ahead in an ever-evolving industrial landscape.

Industrial automation is a game-changer for energy savings. By integrating automated systems into your facility, you can capitalize on manufacturing automation and take control of your energy usage, lower emissions, and cut costs. Whether you’re just looking to upgrade your equipment’s energy efficiency or you want to transform your whole industrial space, the right automation systems can help. When both work in tandem, boosting energy efficiency can be easy.

These systems from us at Metalcraft Automation Group work tirelessly to optimize every aspect of your operations, delivering long-term rewards for both your business and the planet. Now is the time to invest in automation and lead the way toward a more energy-efficient future.