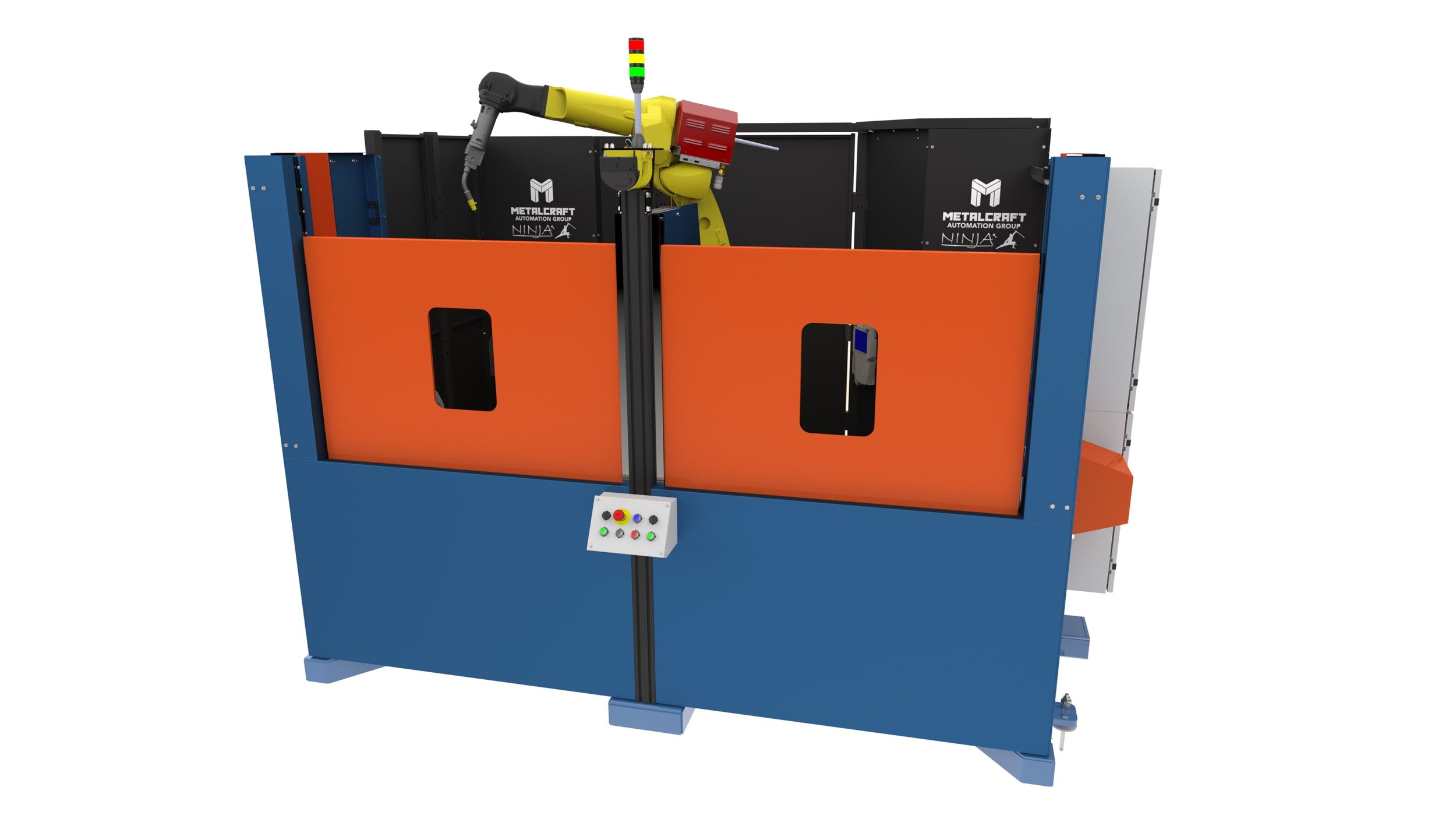

compact Dual Station robotic Welding Cell

The Ninja

offers enhanced productivity by enabling one operator to manage two stations simultaneously.

KEY FEATURES:

Seamless integration with one Fanuc Arc Mate 120iD Robot

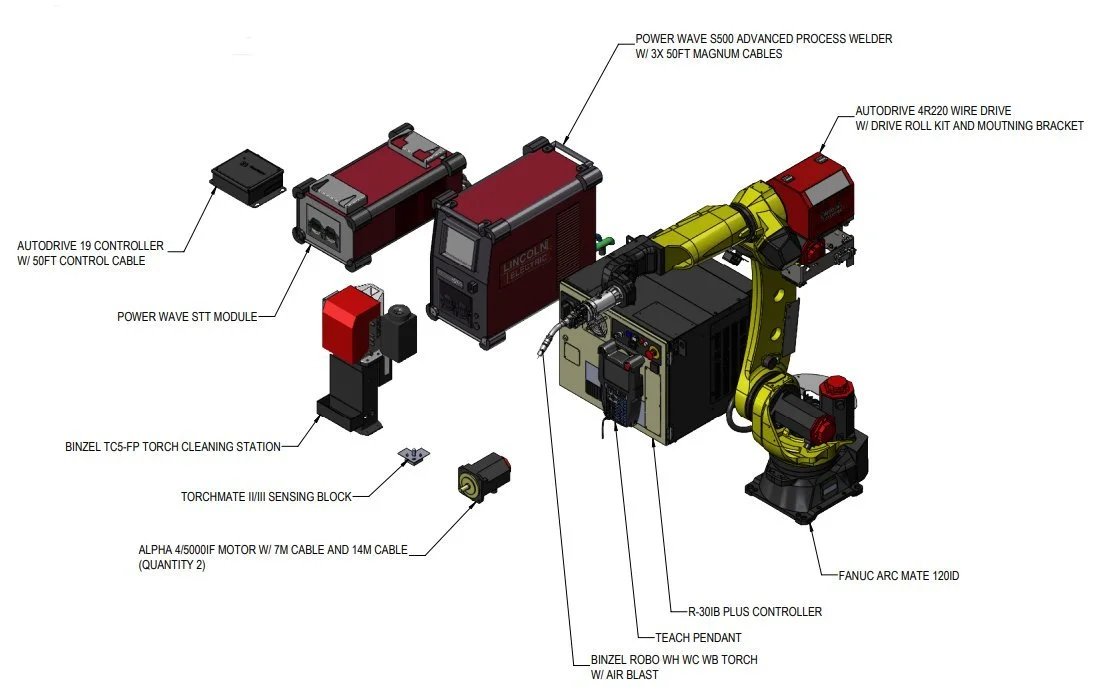

Lincoln Power Wave advanced process welding system (See Image Below)

Two servo motor-controlled Headstock/Tailstock Positioners

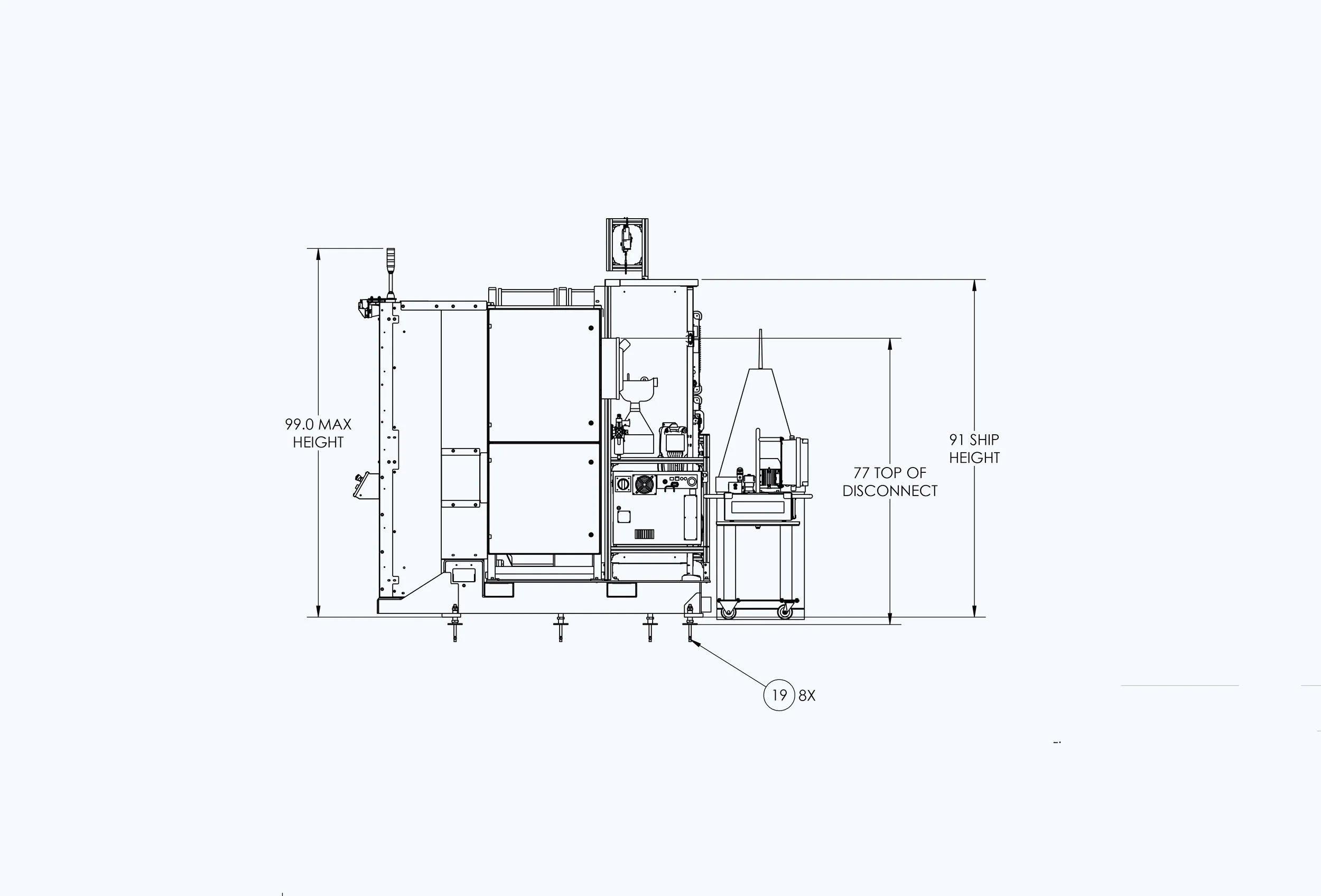

Max part size 19” tall X 29” wide X 35” long

Max payload capacity is 1,000 LBS

Mobile platform base minimizes installation time and cost.

Engineered for high-duty use cycles.

Dual vertical doors with welding screens

Water-cooled torch

Safety scanner

Torch cleaning

BENEFITS:

Consistent weld quality achieved with greater precision

Robust cable management reduces wear and tear.

Easy and convenient installation process

Compact footprint for space optimization

Compliance with OSHA safety standards

IGNITE A BOLD TRANSFORMATION IN YOUR WORKPLACE WITH AUTOMATED WELDING

To learn how Metalcraft Automation Group can improve your manufacturing processes, contact us today!