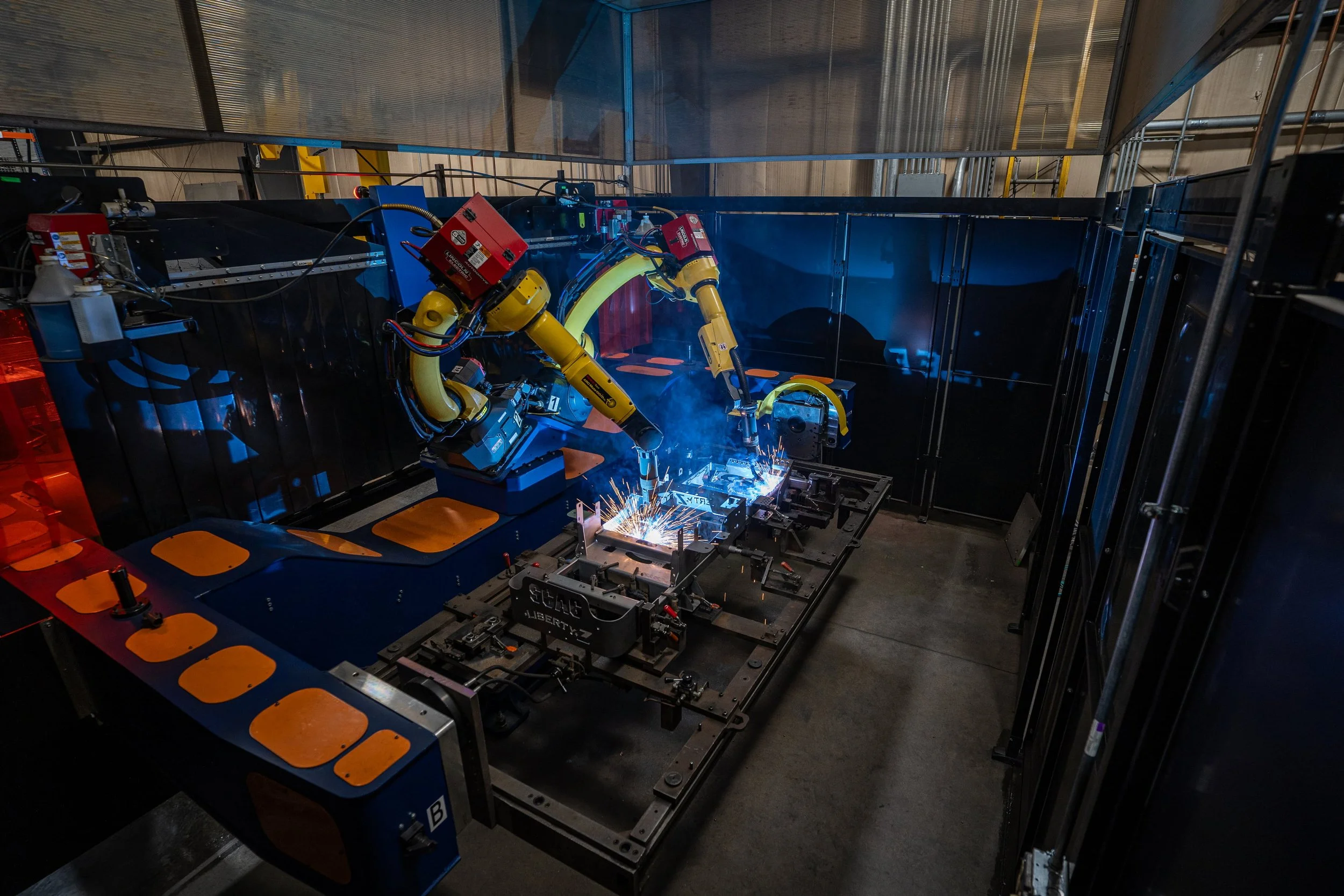

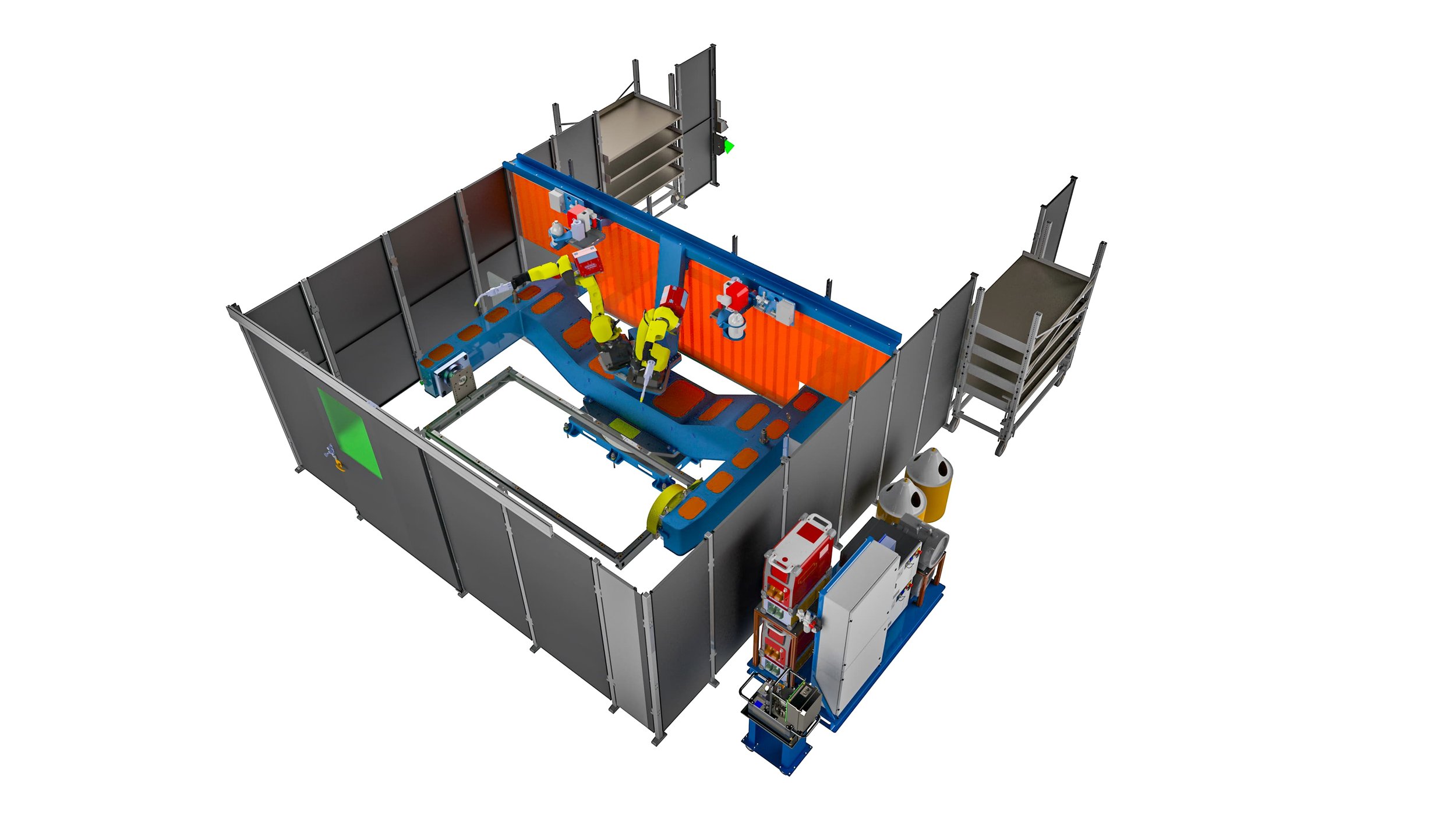

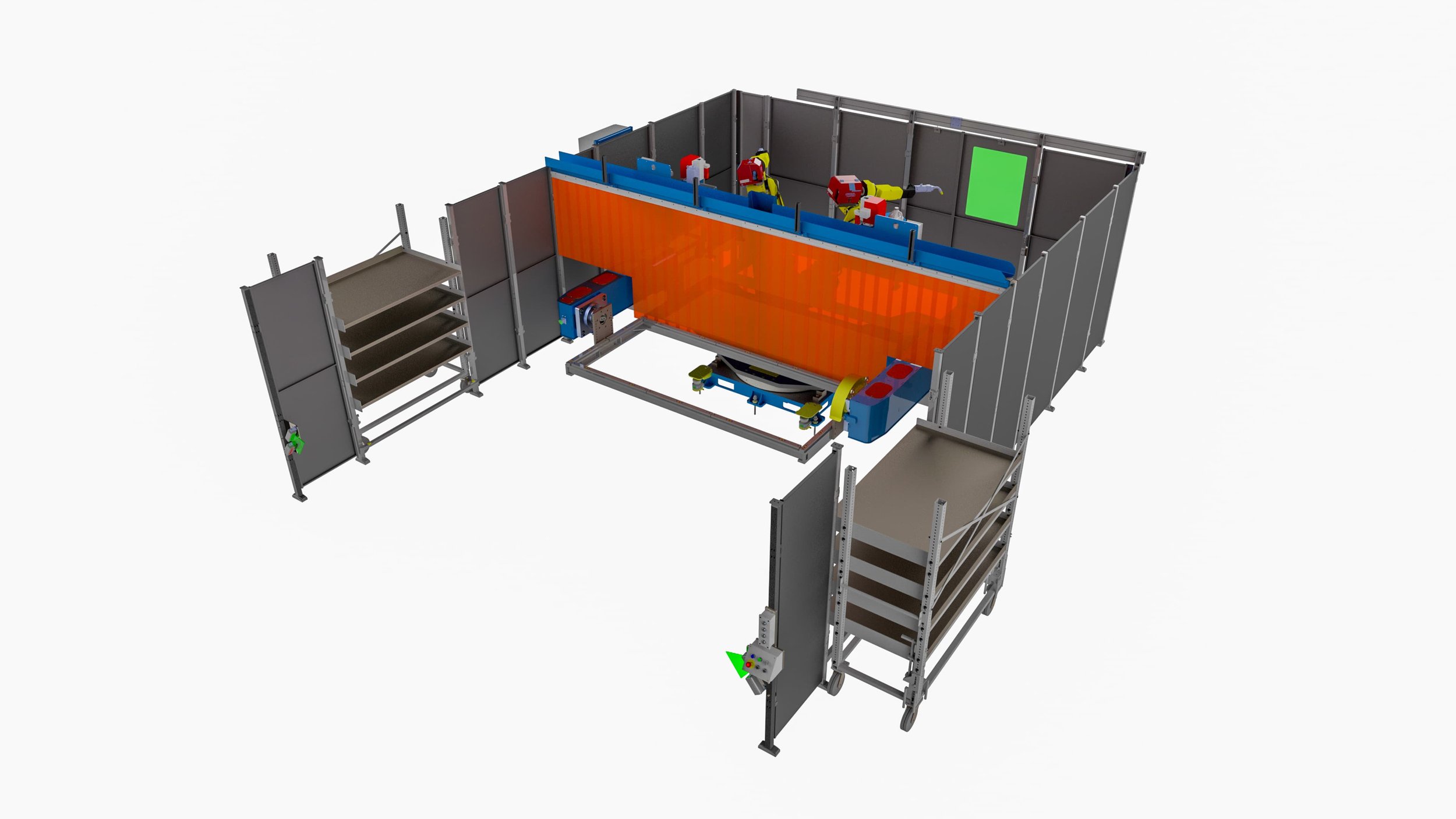

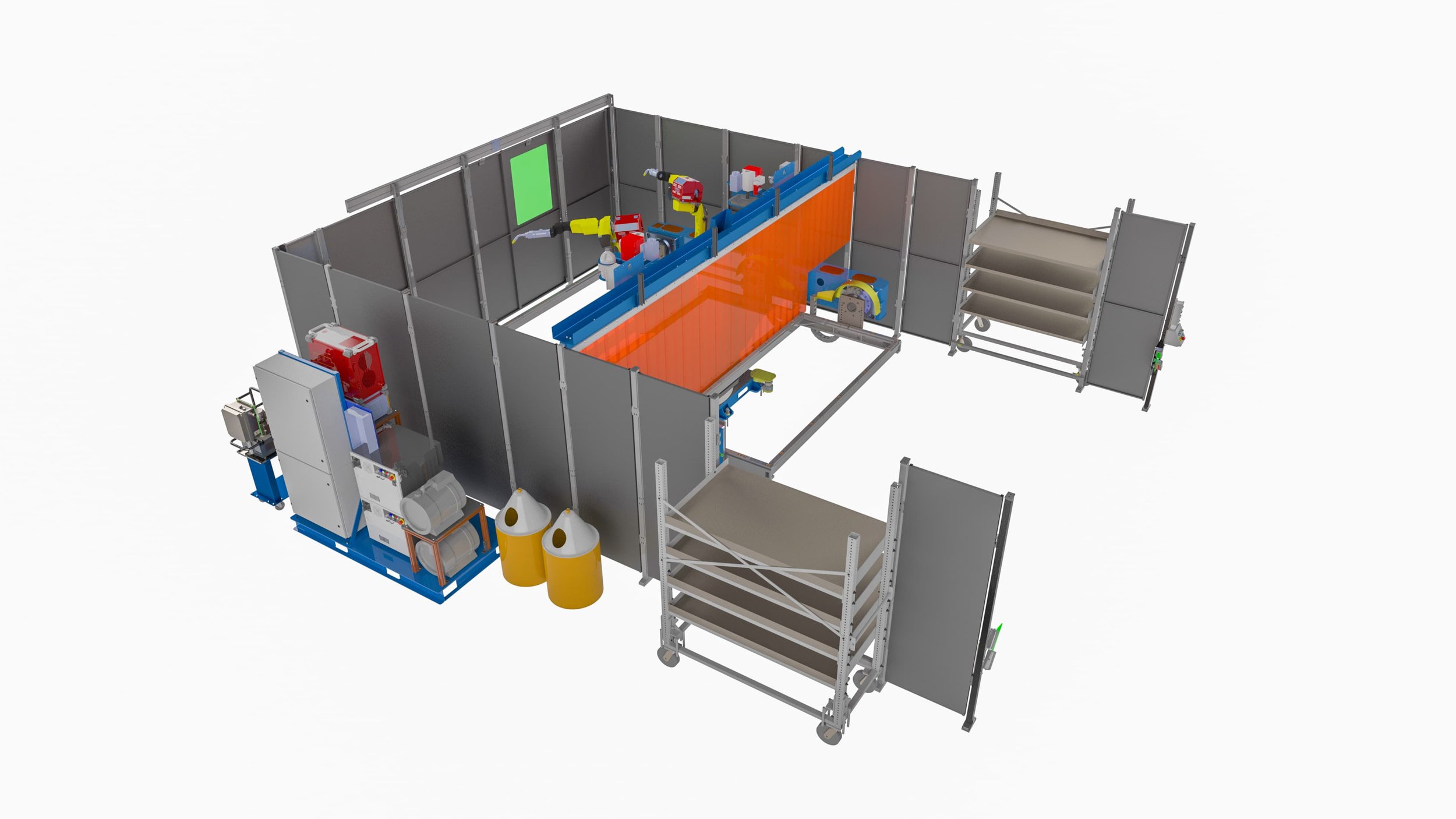

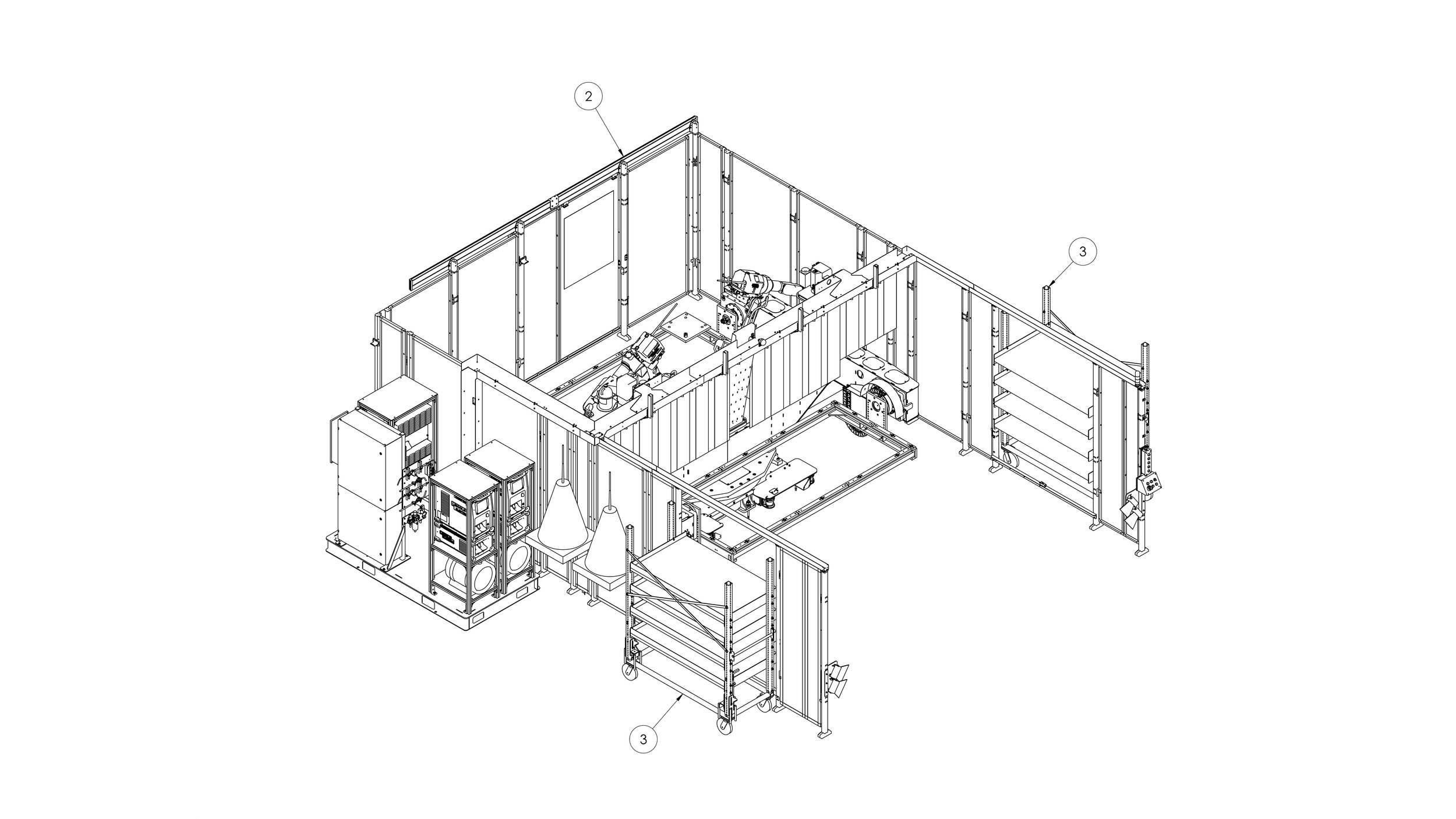

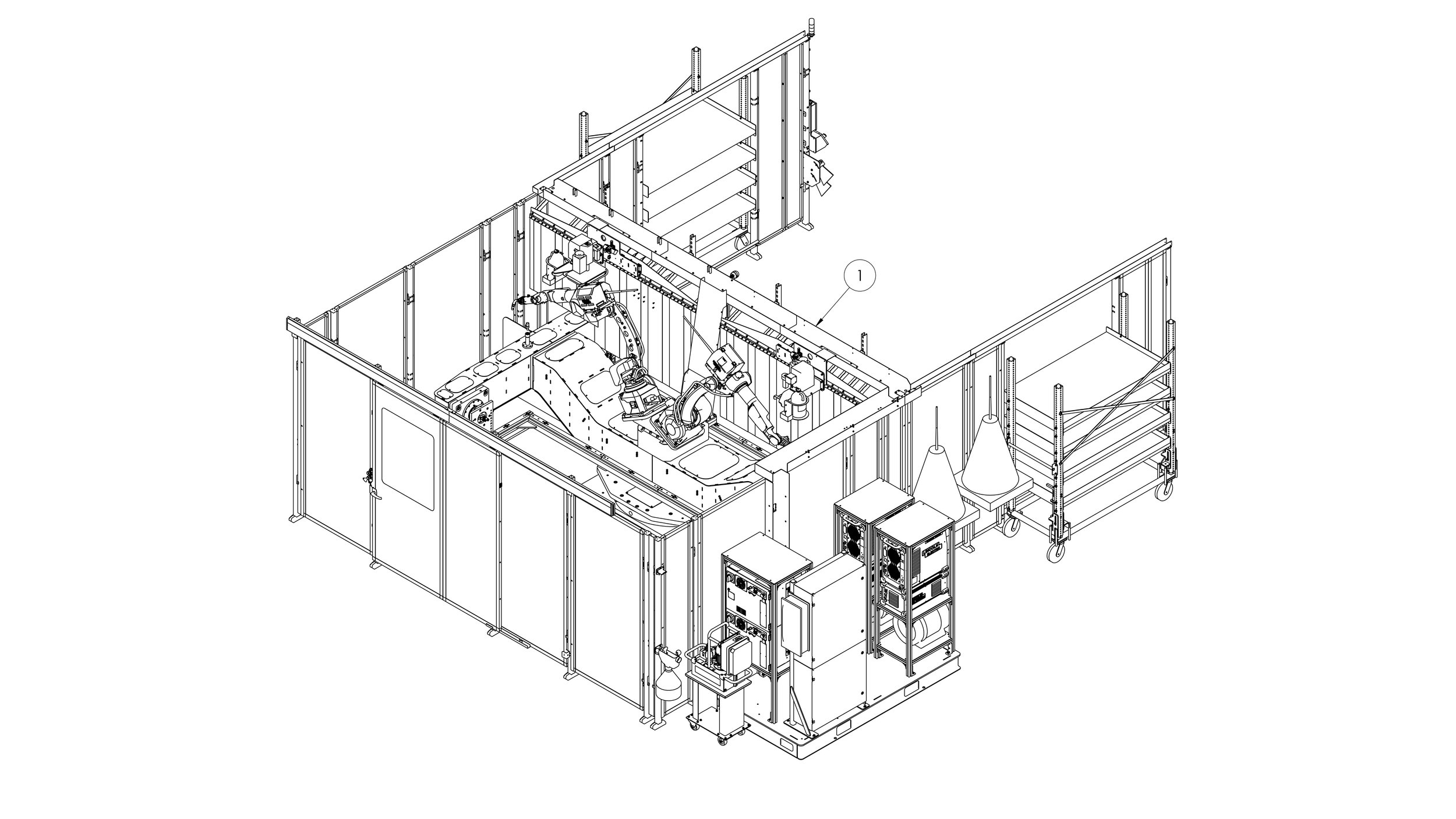

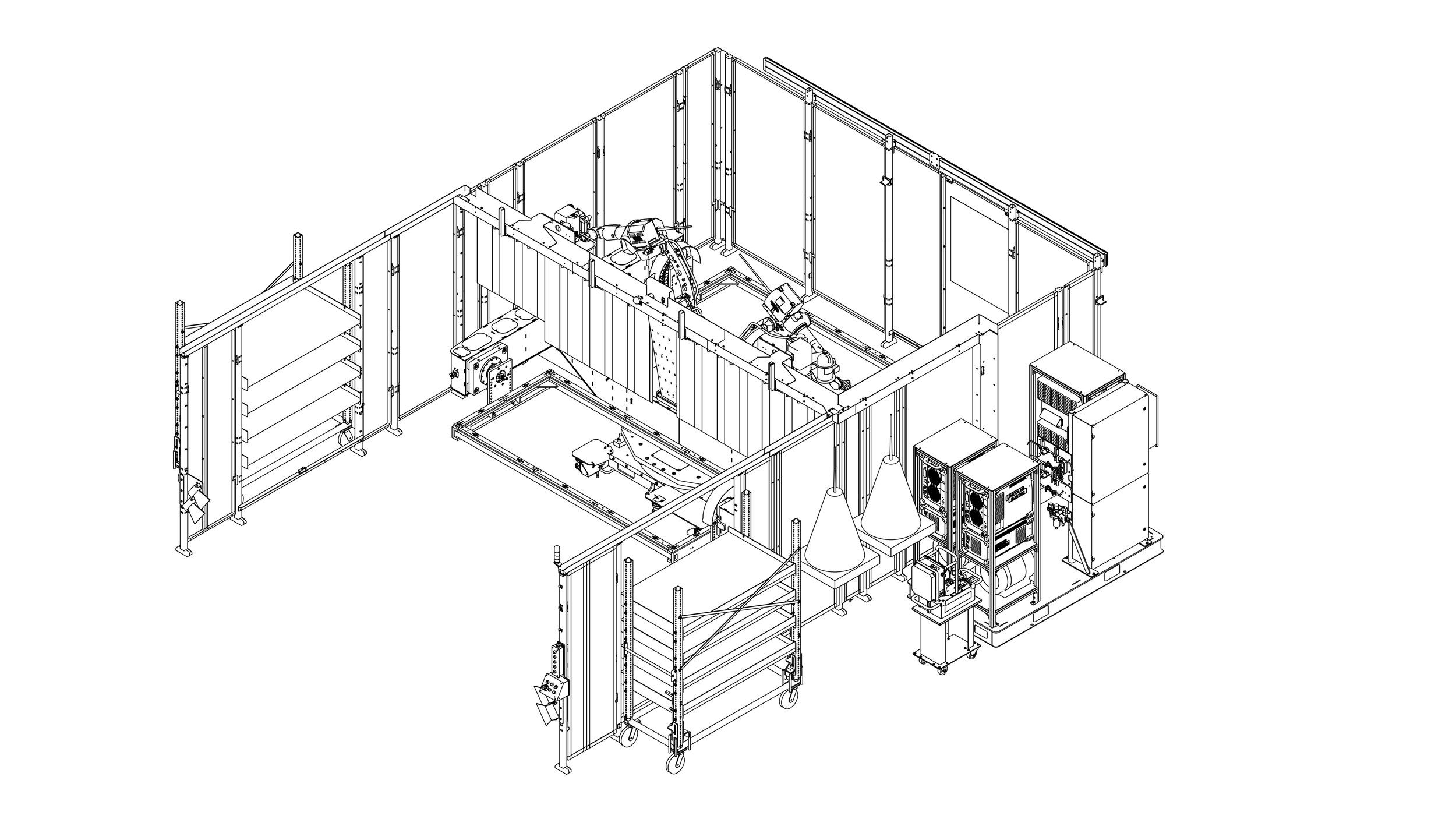

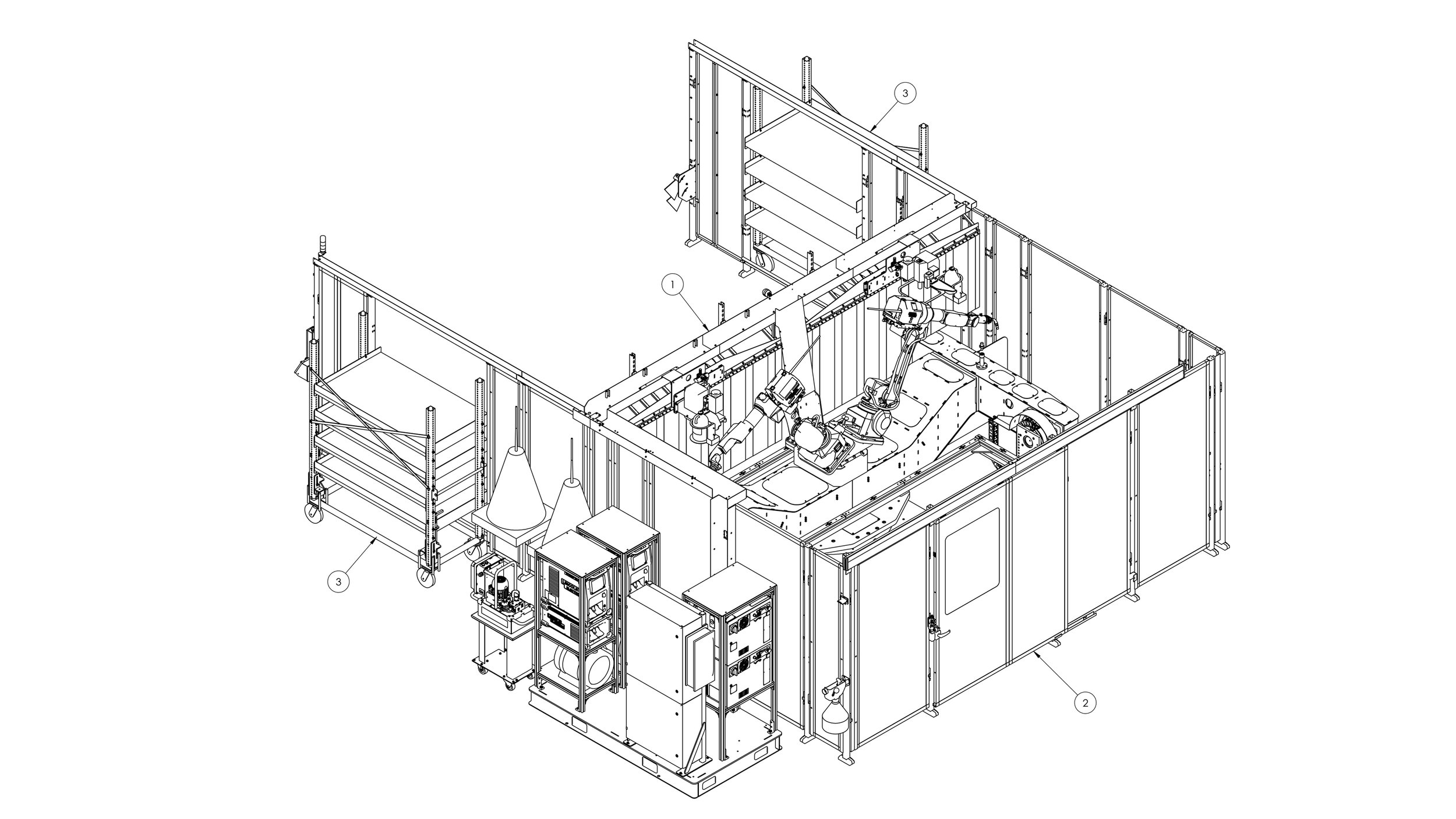

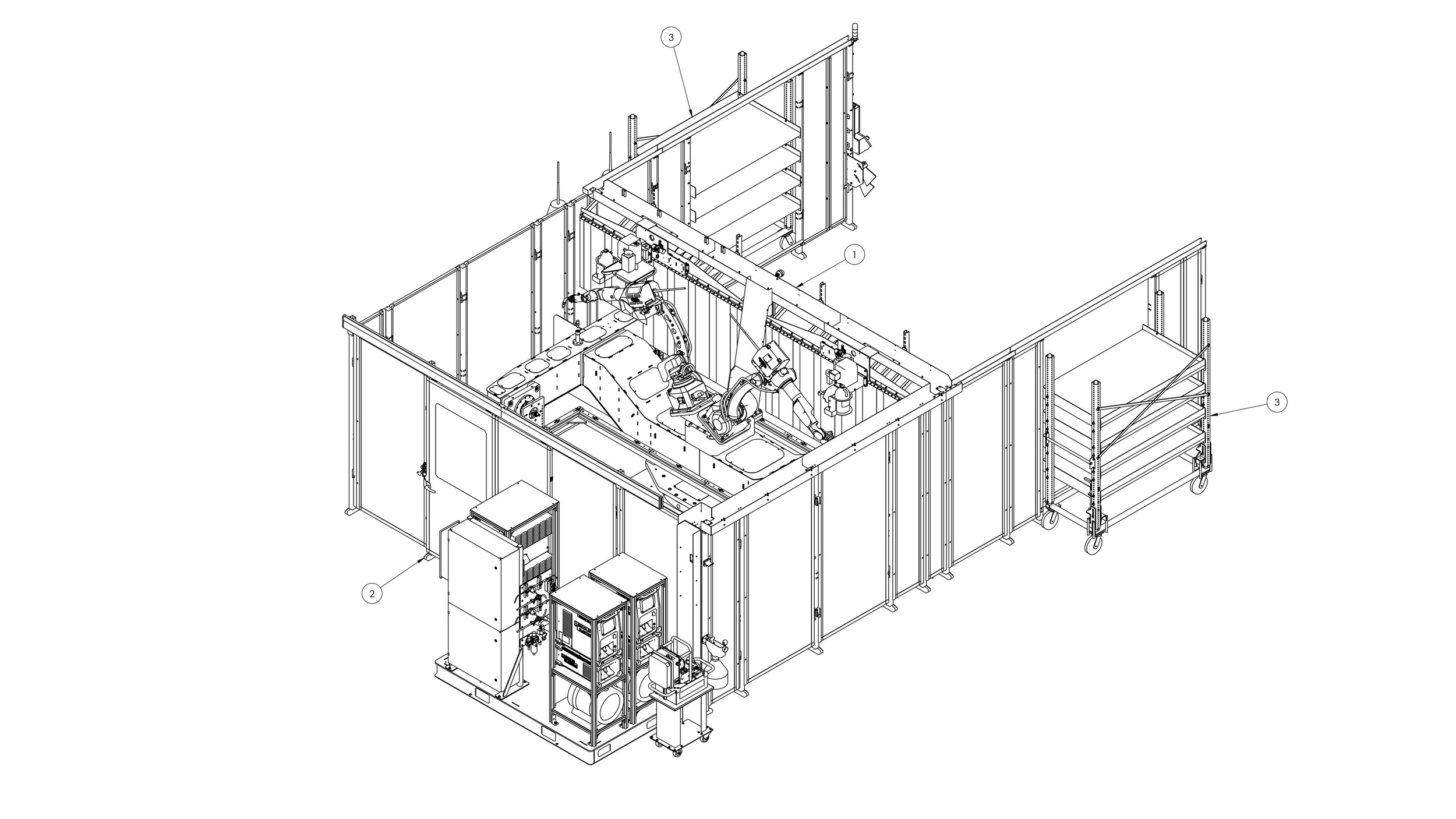

Robotic welding H-Frame Turn Table with two Fanuc Arc Mate Robots

KEY FEATURES:

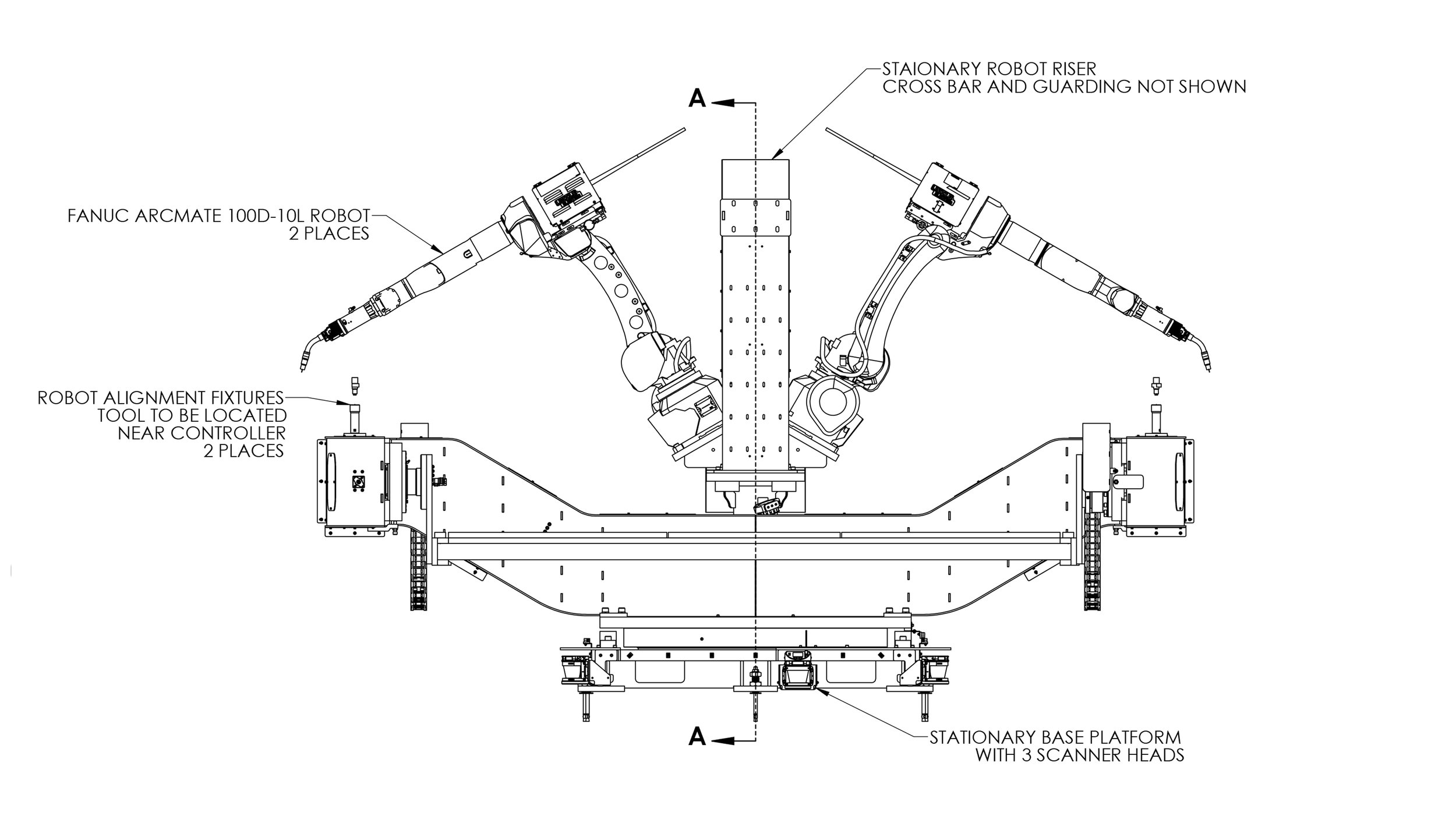

Seamless integration with Two Fanuc Arc Mate 120iD Robots for twice the welding capacity.

Lincoln Power Wave advanced process welding system

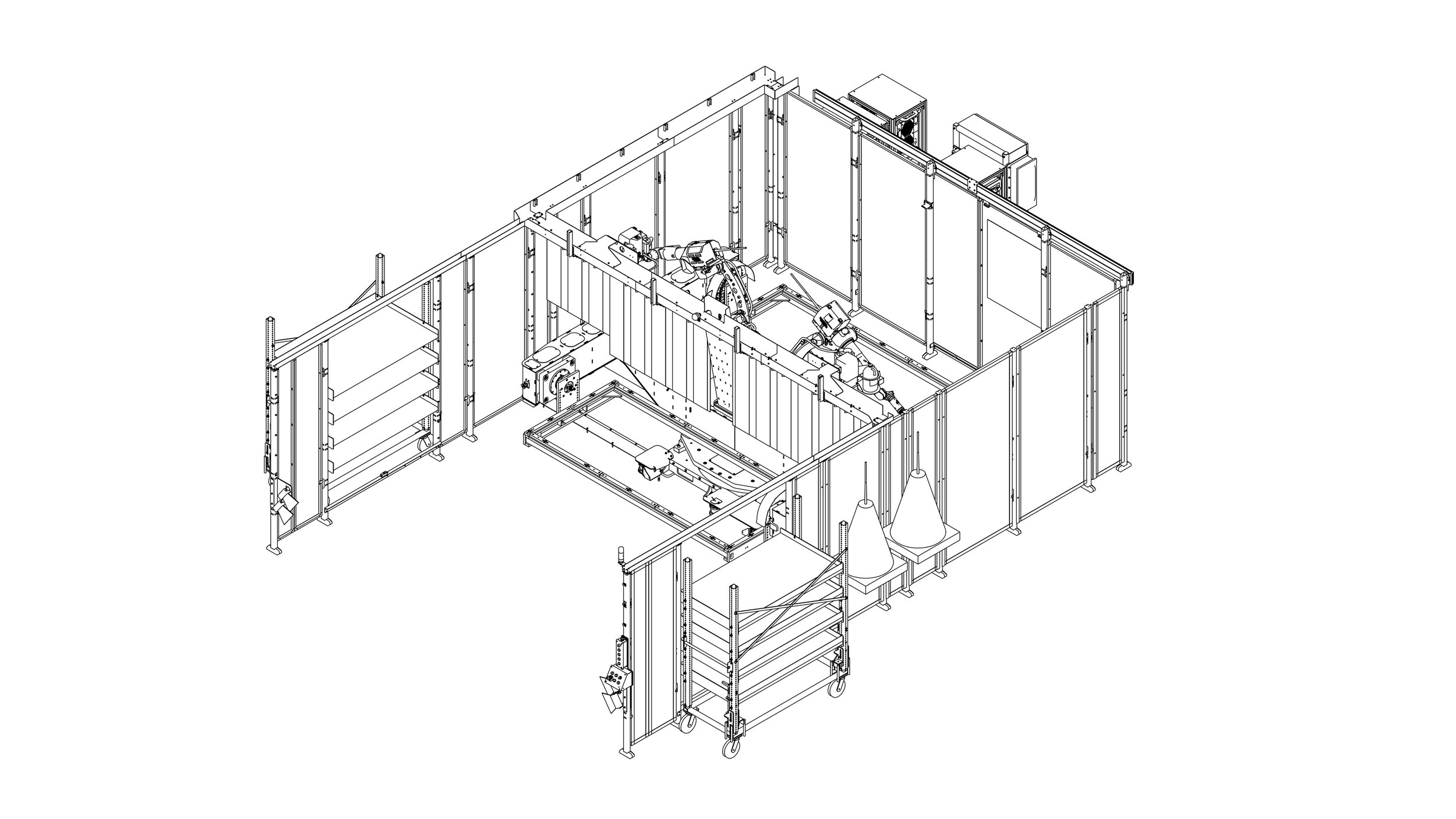

Two servo motor-controlled Headstock/Tailstock Positioners.

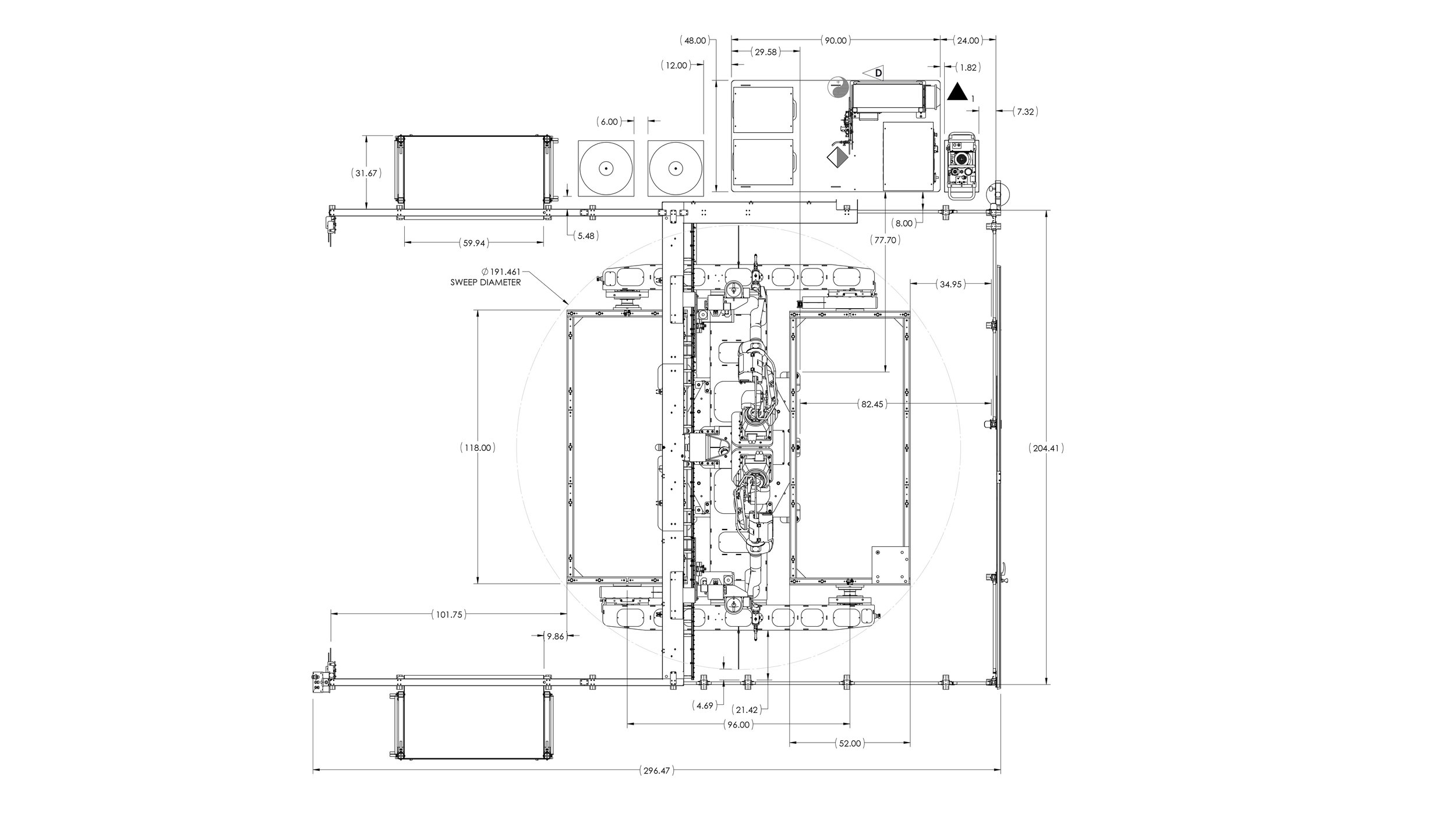

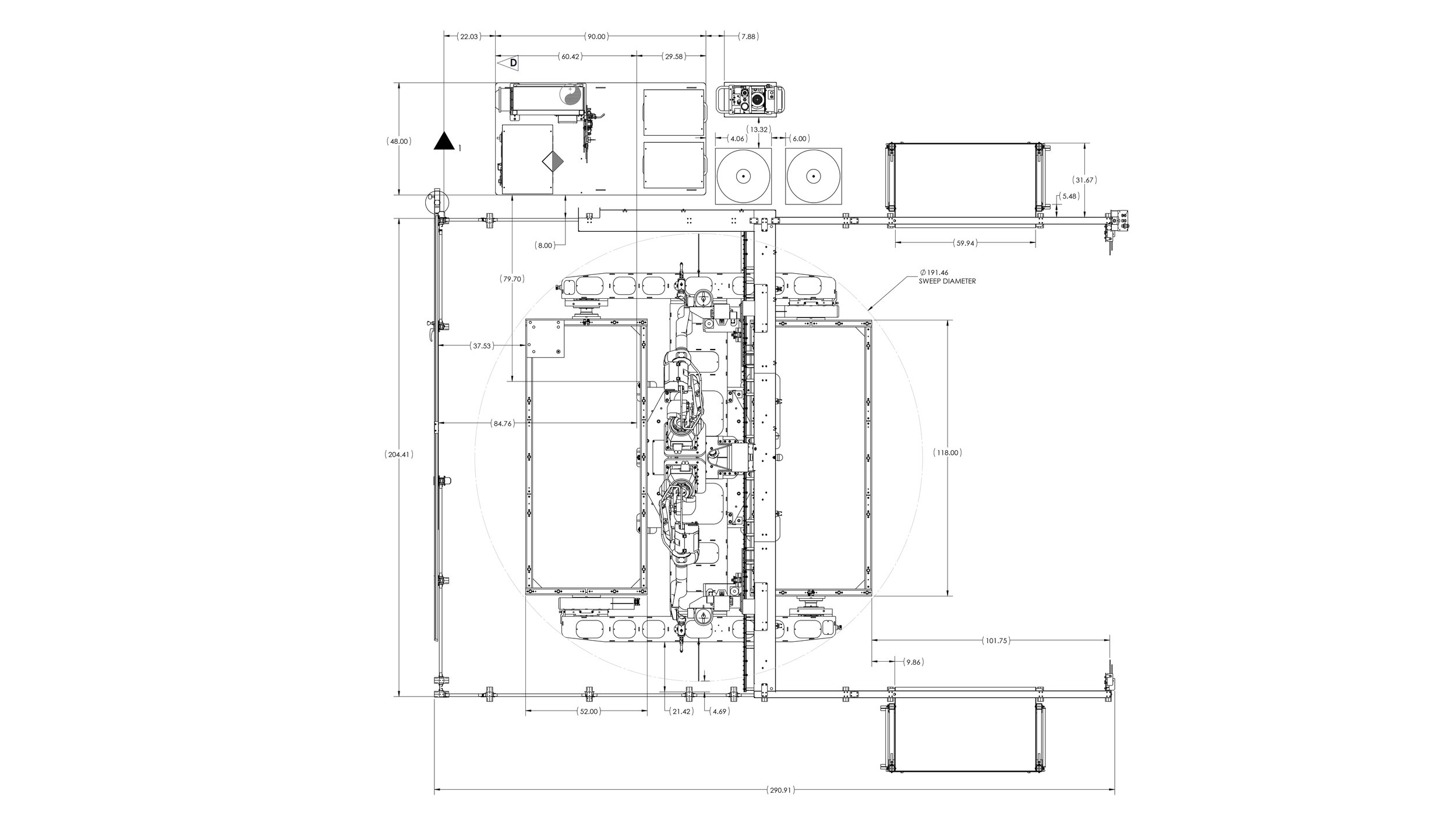

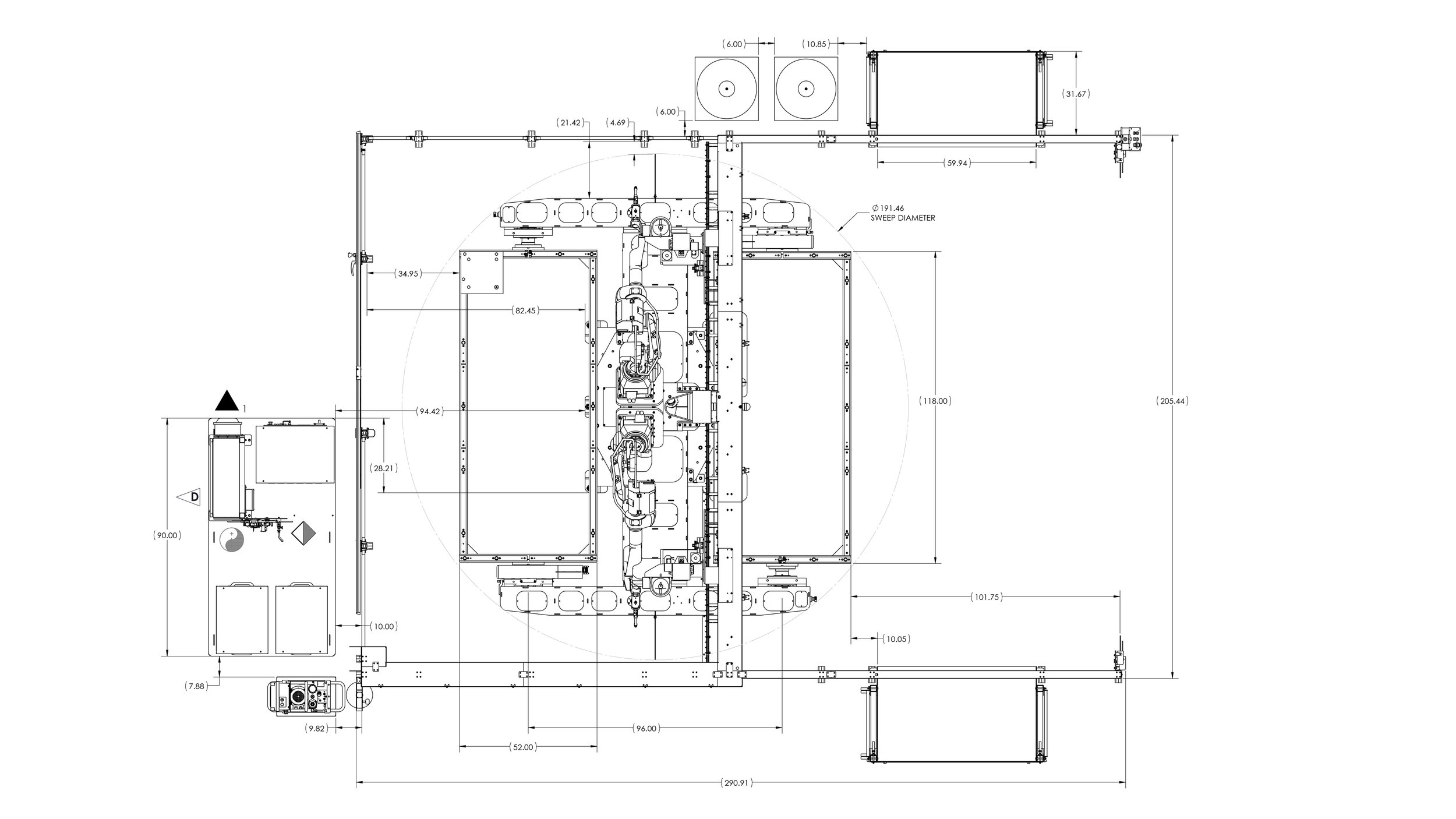

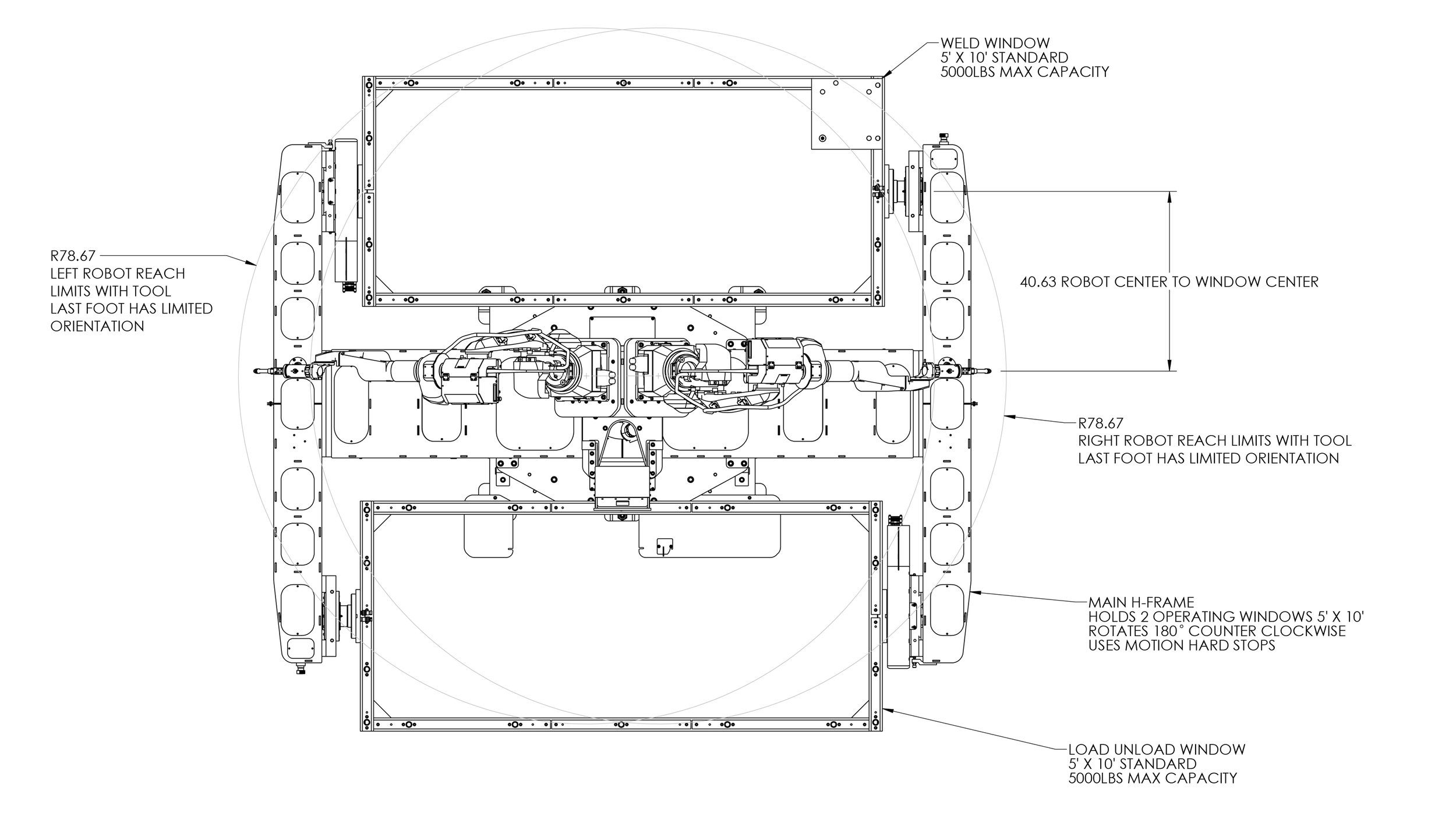

Max part size 60” wide X 120” long

Max payload capacity is 5,000 LBS

The superior precision of our H-Frame indexing is a direct result of its servo motor-driven system and the integration of high-capacity radial bearings.

FEA Optimized H-Frame constructed to virtually eliminate deflection under maximum load conditions.

High-VIZ Indicator Lights provides a clear visual cue for cycle completion.

BENEFITS:

Two robots equals twice the welding capacity.

Consistent weld quality achieved through higher quality construction and precision.

Internal control wiring and hydraulic hoses are protected with outer shell covering that help to reduce wear and tear

Engineered for high-duty use cycles.

Multiple area scanners for increased safety.

Water-cooled torch and Dual Torch cleaning keep your machine running optimally.

Compliant with OSHA safety standards

Easy Maintenance

Multiple Access Panels

Fully sealed radial bearing tail-stock design

Serviced without removing from the frame structure

Allows easy adjustment and alignment without the use of shims

IGNITE A BOLD TRANSFORMATION IN YOUR WORKPLACE WITH AUTOMATED WELDING

To learn how Metalcraft Automation Group can improve your manufacturing processes, contact us today!